In high-precision manufacturing sectors such as MedTech, Aerospace, and Pharmaceutical production, metrology is not a support function—it is a core driver of product quality, regulatory compliance, and patient safety. Whether verifying the geometry of an orthopaedic implant or validating the dimensions of a jet engine component, metrology ensures that each part meets its design intent with accuracy and consistency.

However, as manufacturing technologies evolve—incorporating tighter tolerances, more advanced materials, and increasingly automated inspection processes—the skills required to perform accurate dimensional inspection are also changing. This shift places growing pressure on quality and metrology teams to not only keep up but to lead in capability.

Metrology training programs, once considered a one-time onboarding exercise or niche skill set, are now central to operational resilience and compliance strategies. From first article inspection (FAI) to in-process verification, companies face an urgent need to equip their teams with the knowledge and competencies necessary to adapt to these evolving requirements.

This article offers a detailed, data-informed look at the future of metrology training. Drawing from industry research, regulatory frameworks, and published workforce trend data, we’ll explore:

- The current challenges and skill gaps in metrology

- Industry trends shaping future training needs

- Competencies required for the next generation of metrologists

- Evidence-based best practices for training implementation

- Recommendations for building a resilient and future-ready workforce

This is not a theoretical discussion. The insights presented here are grounded in factual reporting, empirical studies, and regulatory trends, intended for professionals responsible for quality assurance, metrology strategy, and manufacturing excellence.

The State of Metrology Today

Metrology, the science of measurement, is foundational to quality assurance in manufacturing. In sectors such as medical devices and aerospace, where component failures can directly impact human safety, the accuracy, repeatability, and traceability of inspection data are not optional; they are regulatory requirements.

A Critical Yet Understaffed Function

Despite its importance, metrology is often cited as one of the least-resourced areas within manufacturing operations. According to a 2022 survey by the American Society for Quality (ASQ), 43% of quality professionals reported a shortage of skilled metrologists and CMM programmers within their organisation. This is consistent with findings from the UK’s National Physical Laboratory (NPL), which has documented a persistent skills shortage in dimensional metrology since 2018.

The impact is felt across manufacturing plants. Without skilled personnel, companies face:

- Extended inspection cycle times

- Delays in product validation and release

- Inaccurate data leading to non-conformances or false rejections

- Increased risk of regulatory findings during audits

Data Visibility and the Role of Metrology

With the rise of Industry 4.0, data generated from inspection processes is increasingly expected to flow into larger quality management systems (QMS), manufacturing execution systems (MES), and product lifecycle management (PLM) platforms. However, this integration often fails in the absence of structured measurement routines, validated software use, and trained personnel capable of interpreting GD&T data in digital environments.

In a 2023 study by Deloitte, 67% of MedTech manufacturers cited “insufficient data trustworthiness” in their inspection processes as a key barrier to automation and digital transformation.

Regulatory Expectations

Global regulatory bodies continue to raise expectations around inspection traceability and operator qualification. For example:

- ISO 13485:2016 requires that personnel affecting product quality be “competent on the basis of appropriate education, training, skills, and experience.”

- FDA 21 CFR Part 820 (Quality System Regulation) mandates documented evidence of personnel qualification related to inspection and testing activities.

- In 2021 alone, over 30% of FDA warning letters to device manufacturers included citations related to inadequate inspection or failure to maintain control over measuring equipment and processes.

These figures suggest that training is not merely a best practice—it is a compliance imperative.

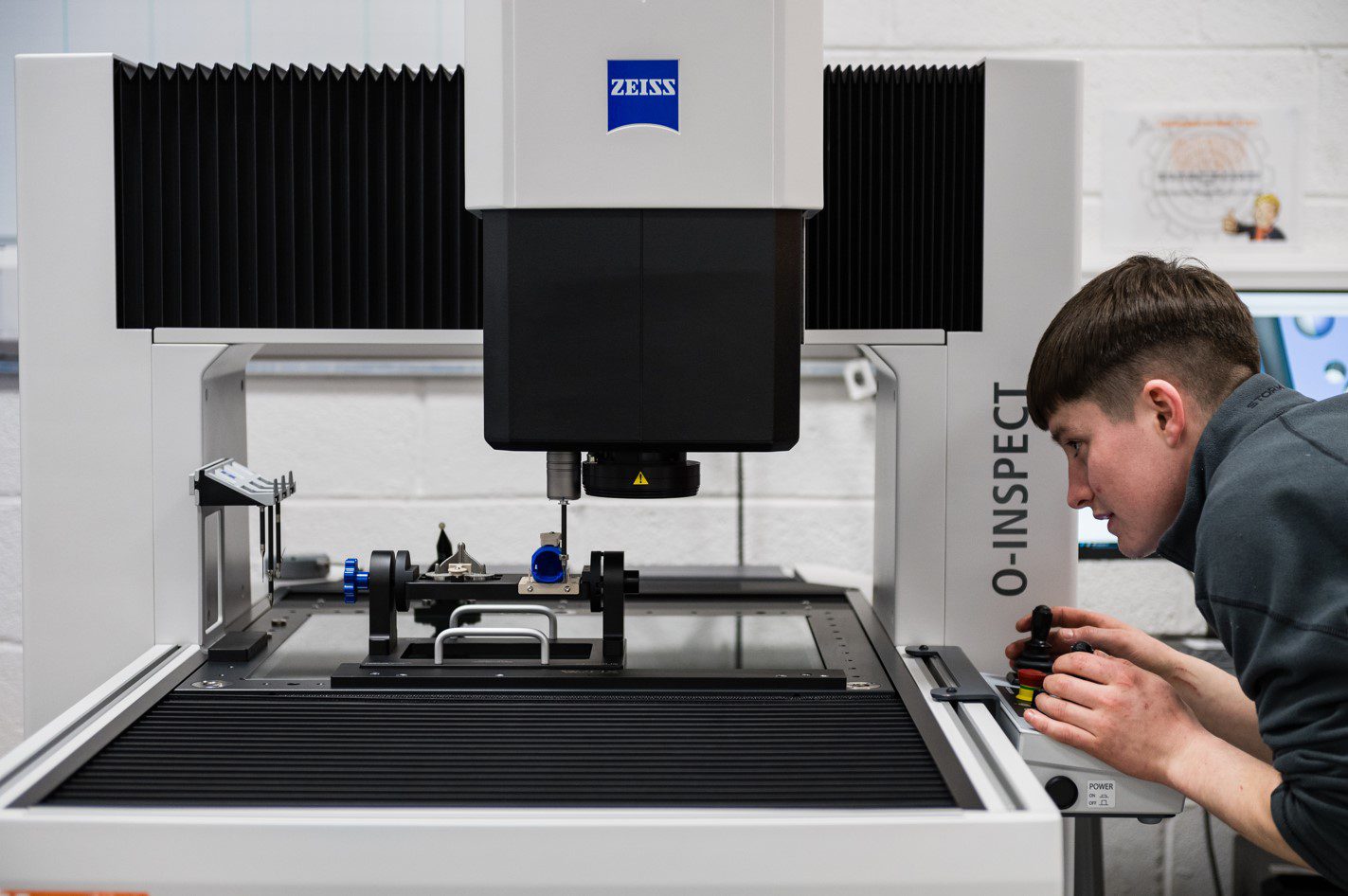

Technology Outpacing Training

In addition to compliance pressures, technology adoption in metrology labs is outpacing available skillsets. The deployment of multi-sensor CMMs, non-contact vision systems, and programmable fixtures requires cross-disciplinary knowledge, combining mechanical engineering, software programming, and quality systems understanding.

Yet most vocational and academic training programs do not offer integrated metrology education. Instead, companies often rely on internal knowledge transfer or vendor-specific training, which may not fully prepare staff for broader challenges in dimensional verification or automated inspection system setup.

Skill Gaps and Workforce Trends

The metrology profession sits at the intersection of engineering precision, regulatory compliance, and digital transformation. Yet, despite its critical role, industry data indicates that metrology teams are increasingly under-skilled for the challenges ahead. Addressing this growing skills gap is essential not just for operational continuity but also for maintaining regulatory standing and avoiding costly delays or rework.

Documented Skills Deficiencies

A recurring theme in industry reports is the shortage of personnel with essential metrology competencies. A 2021 survey by the National Institute for Metalworking Skills (NIMS) found that:

- 60% of manufacturers struggle to find employees proficient in Geometric Dimensioning and Tolerancing (GD&T).

- 49% report difficulty hiring individuals with CMM programming experience.

- 40% cite a lack of understanding of measurement uncertainty and Gage R&R studies.

These competencies are foundational for ensuring that inspection results are valid, repeatable, and defensible in a regulated environment.

A separate study conducted by the UK’s High Value Manufacturing Catapult identified a significant lack of metrology knowledge even among engineering graduates entering advanced manufacturing roles. This gap spans both dimensional inspection and broader measurement system analysis, including software proficiency and process capability assessment.

Ageing Workforce and Knowledge Drain

The skill gap is exacerbated by an ageing workforce. According to a 2022 report by Deloitte and The Manufacturing Institute, 25% of the U.S. manufacturing workforce is aged 55 or older. In sectors such as quality assurance and metrology, where knowledge is often informal and experience-based, the impending retirement of senior staff presents a serious risk.

Without structured training programs and documented processes, tacit knowledge in inspection methodology, fixture setup, and measurement system evaluation risks being lost. This can delay production launches, reduce throughput, or compromise compliance audits.

Emerging and Evolving Roles

As automation increases, the role of the metrologist is also changing. Today’s metrology professionals are expected to bridge traditional inspection work with skills in software, data analytics, and automation. New hybrid roles are emerging, such as:

- Quality Data Analyst – responsible for interpreting statistical process control (SPC) outputs and integrating data across systems.

- Metrology Automation Engineer – oversees the integration of robotic inspection cells and programmable fixtures.

- Digital Metrology Specialist – manages digital twins, offline programming, and cloud-based measurement data.

In many facilities, these hybrid roles are not yet formalised, leading to mismatched expectations and unfilled capability gaps.

Job Postings Reflect Changing Expectations

A keyword analysis of job postings on platforms such as Indeed, LinkedIn, and industry job boards (Q4 2023) shows a significant increase in required skills related to:

- GD&T proficiency (up 41% YoY)

- Programming knowledge (PC-DMIS, MODUS, or MCOSMOS)

- Statistical software (Minitab or JMP)

- ISO 13485 or AS9100 familiarity

Notably, employers now increasingly expect candidates to understand both inspection methodology and data interpretation, reflecting the convergence of quality and data science in manufacturing settings.

Industry Demands Driving Training Evolution

The evolution of metrology training is being shaped not just by internal workforce dynamics but by external industry and regulatory forces that are transforming how quality and inspection functions operate. In precision-focused sectors such as MedTech, Aerospace, and Personal Care manufacturing, the environment is marked by tighter tolerances, more complex geometries, accelerated product launches, and stricter regulatory scrutiny.

These realities are increasing the demand for metrology professionals who are not only competent in traditional inspection techniques but also adept with modern equipment, digital workflows, and analytical thinking.

Tighter Tolerances and More Complex Parts

In medical device and aerospace manufacturing, product designs are becoming increasingly miniaturised and geometrically complex. Features such as internal undercuts, micro-cavities, and organic surfaces require inspection solutions that go beyond basic 2D measurement tools.

According to a report by the U.S. Food & Drug Administration (FDA), the top three root causes of inspection-related product recalls in the medical device industry between 2018 and 2022 were:

- Inaccurate dimensional measurements

- Inadequate inspection method validation

- Unqualified personnel performing inspection

As a result, training must now include not just theory but practical proficiency with multi-sensor systems (CMMs, vision systems, laser scanners) and fixture-based inspection routines.

Regulatory Compliance is Becoming More Competency-Focused

Regulatory bodies are placing growing emphasis on evidence of personnel competency, not just the presence of a quality system. For example:

- ISO 13485:2016 explicitly mandates that training be documented and competency be assessed for any role impacting product quality.

- EU MDR 2017/745 requires manufacturers to demonstrate that their quality personnel are appropriately trained and regularly updated on best practices.

- FDA QSIT (Quality System Inspection Technique) includes direct audit checks on how training effectiveness is validated for operators conducting inspections or testing.

These frameworks are shifting the responsibility from simply “having training” to demonstrating measurable outcomes of training. In this context, casual on-the-job learning is insufficient. Structured, documented, and evaluated training programs are now expected.

Digitalisation and Industry 4.0 Pressures

The transition to digital manufacturing environments—including smart inspection stations, real-time SPC, and data-driven decision-making—requires metrologists to understand not just measurement but how that data integrates into digital quality infrastructures.

Key trends driving this include:

- Adoption of Quality 4.0 frameworks, as outlined by the World Economic Forum, which emphasise the connection between measurement data and production analytics

- Growing use of digital twins for offline inspection programming and process simulation

- Integration of PLM and MES platforms with inspection systems to create traceable digital audit trails

For quality and engineering managers, this means that training now needs to bridge traditional tactile metrology and digital analytics, including data interpretation, system interoperability, and automated feedback loops.

Product Development Cycles Are Shortening

Manufacturers are launching new products faster than ever to remain competitive. A 2023 benchmark study by McKinsey found that MedTech companies aim to reduce time-to-market by 20–30% over the next three years. For quality and metrology teams, this translates to:

- Shorter windows for inspection routine development

- More frequent design revisions requiring updated programming

- A heavier reliance on FAI, in-process validation, and Gage R&R

All of this puts pressure on teams to be trained in rapid measurement development techniques, off-line CMM programming, and design-to-inspection alignment using CAD data.

Increased Demand for Audit Readiness

Finally, metrology data is increasingly being scrutinised during third-party audits, whether regulatory or customer-based. As OEMs tighten their quality agreements with suppliers, more emphasis is being placed on:

- Measurement traceability

- Statistical process understanding (capability indices, Gage R&R)

- Documentation of training logs and competency verification

Training programs must now prepare professionals not only to perform inspections correctly but also to defend their methodology and results under formal audit conditions.

Core Competencies for the Future Metrologist

The role of the metrologist is no longer limited to manual measurement or basic inspection tasks. As inspection processes become more automated, data-centric, and integrated into digital ecosystems, the required skill set has expanded significantly.

Future-ready metrology professionals must possess a combination of technical measurement expertise, software proficiency, regulatory awareness, and analytical capability. These competencies must be measurable and aligned with both operational KPIs and compliance standards.

Below is a breakdown of the essential competencies, backed by job market analysis, industry standards, and academic program requirements.

1. Dimensional Inspection Fundamentals

What it entails:

- Mastery of 2D and 3D inspection techniques

- Use of tactile and non-contact equipment (CMMs, vision systems, laser scanners)

- Understanding of feature-based measurement vs. traditional dimensions

Why it matters:

A 2023 analysis of job descriptions on LinkedIn showed that 88% of roles titled Metrology Engineer or CMM Technician listed “dimensional inspection” as a required skill. This remains the foundational competency across all sectors.

2. GD&T (Geometric Dimensioning and Tolerancing)

What it entails:

- Interpreting engineering drawings with GD&T annotations

- Applying tolerances to 3D models

- Ensuring compliance with ASME Y14.5 or ISO 1101 standards

Why it matters:

Improper understanding of GD&T is a common cause of non-conformances and audit findings. In a report by ASQ, 61% of QA teams cited GD&T interpretation errors as a frequent source of internal rework or delay.

3. Metrology Software Proficiency

What it entails:

- Ability to program and edit inspection routines using major CMM software:

- PC-DMIS (Hexagon)

- MCOSMOS and MiCAT Planner (Mitutoyo)

- Renishaw MODUS

- Zeiss Calypso

- Virtual DMIS and Zone 3 (OGP)

Why it matters:

Software fluency allows metrologists to create optimised, repeatable inspection routines tailored to production timelines. In many facilities, the lack of in-house programming capability results in long lead times and external service dependency.

Market insight:

In a 2022 Verisurf survey, 72% of quality departments reported CMM programming capability as their top unmet metrology need.

4. Statistical Process Control (SPC) and Data Analysis

What it entails:

- Applying SPC principles such as Cp, Cpk, and Pp, Ppk

- Conducting Gage R&R studies to assess measurement system variability

- Using statistical software (e.g., Minitab, JMP) for data validation and reporting

Why it matters:

As Quality 4.0 matures, inspection professionals are expected to interpret process capability data and support closed-loop quality systems. ISO 13485:2016 and IATF 16949 explicitly reference SPC as part of the control plan.

5. Fixture-Based Inspection Knowledge

What it entails:

- Understanding how metrology fixtures influence measurement repeatability

- Verifying fixture setup using Gage R&R and equivalency studies

- Collaborating with design and tooling engineers to optimise inspection strategy

Why it matters:

Incorrect fixture use or setup is a major source of variation. A study from the European Metrology Research Programme (EMRP) highlighted that up to 35% of measurement errors in medical device inspection stem from poor fixturing practices.

6. Regulatory Awareness and Traceability

What it entails:

- Understanding the documentation requirements of ISO 13485, FDA 21 CFR 820, EU MDR

- Generating FAIR (First Article Inspection Reports), ISIRs, and calibration certificates

- Ensuring full traceability of inspection results to design specifications and customer requirements

Why it matters:

Regulators now routinely review how inspection methods are documented, validated, and executed. Training must prepare staff to produce and defend traceable measurement records during audits.

7. Communication and Cross-Functional Collaboration

What it entails:

- Collaborating with design, tooling, production, and quality teams

- Communicating inspection results and non-conformances clearly

- Supporting root cause analysis and continuous improvement initiatives

Why it matters:

Metrologists are no longer isolated technicians. Their insights are central to product validation, supplier quality control, and regulatory readiness. Communication skills are critical for translating complex measurement data into actionable information.

Training Delivery Models: What Works?

As the demands on metrology teams continue to grow, companies face an important question: How should they train their personnel to meet new technical, regulatory, and operational requirements? Choosing the right training model is not just a matter of logistics—it directly affects workforce readiness, inspection quality, and audit outcomes.

This section evaluates various training delivery models in terms of effectiveness, scalability, and return on investment (ROI), drawing on industry benchmarks, case studies, and academic research.

In-House Training Programs

Overview:

In-house training programs are developed internally and often delivered by experienced staff, metrology leads, or quality engineers.

Pros:

- Customised to equipment and processes

- Immediate relevance to current production

- Allows hands-on practice with live parts and fixtures

Cons:

- Knowledge transfer is often informal and undocumented

- Difficult to scale or standardise

- Heavily reliant on the availability of senior staff

Data Point:

A 2022 survey by the UK National Physical Laboratory (NPL) found that 48% of manufacturers using in-house training lacked structured assessment mechanisms, raising concerns about competency validation.

OEM and Vendor-Certified Training

Overview:

Training provided by equipment manufacturers (e.g. Hexagon, Mitutoyo, OGP, Renishaw) either at their sites, online, or through on-site sessions.

Pros:

- High technical accuracy and alignment with system capabilities

- Often includes certification upon completion

- Beneficial for equipment-specific skills like CMM programming

Cons:

- Typically focused only on proprietary platforms

- May not address broader metrology concepts (e.g., GD&T, SPC)

- Can be expensive and time-limited

Insight:

According to a 2021 Hexagon Manufacturing Intelligence report, clients who sent technicians to OEM training experienced a 28% improvement in programming efficiency after completion, particularly when paired with simulation-based learning modules.

Third-Party Training Providers

Overview:

External organisations offer standardised training in core metrology subjects, including GD&T, SPC, Gage R&R, and advanced inspection techniques.

Pros:

- Neutral and standards-based (ASME, ISO)

- Often recognised by auditors and regulators

- Can be adapted for in-house delivery or remote access

Cons:

- May lack alignment with specific in-house processes

- Requires coordination to integrate with production schedules

Best Practice:

Leading aerospace and MedTech companies often combine third-party theory courses with practical on-site assessments to close the gap between knowledge and application.

Blended Learning Approaches

Overview:

Combines in-person instruction with online modules, video tutorials, interactive simulations, and assessments.

Pros:

- Scalable across multiple sites and regions

- Enables continuous learning and on-demand access

- Tracks progress and competencies digitally

Cons:

- Requires a robust LMS (Learning Management System)

- Digital engagement varies among staff

Trend Insight:

A 2023 study by the Manufacturing Institute found that companies using blended learning saw a 20–35% improvement in employee retention in technical roles, particularly when content was linked to professional certification or job progression.

Simulation and Digital Twin-Based Training

Overview:

Advanced programs use CAD data, virtual CMM environments, or augmented reality (AR) to replicate inspection scenarios.

Pros:

- Enables training before physical parts or tools are available

- Reduces downtime on production equipment

- Ideal for validating CMM routines, FAI plans, and fixture usage

Cons:

- High upfront investment in software and content development

- Requires strong digital literacy

Example:

A pilot program conducted by a Tier 1 MedTech supplier in 2022 showed that training new staff using digital twin environments reduced CMM programming errors by 40% in the first six months, compared to traditional training alone.

ROI of Structured Training Programs

Structured training has been shown to yield tangible operational and compliance benefits:

- Error reduction: Well-trained staff reduce dimensional inspection errors, decreasing scrap and rework.

- Audit readiness: Competency documentation and skill matrices are increasingly expected in ISO/FDA audits.

- Throughput gains: Skilled metrologists optimise routines faster, increasing inspection capacity.

According to internal benchmarking from several MedTech manufacturers, the ROI of structured training initiatives typically ranges from 3:1 to 6:1 over a two-year horizon, when factoring in reduced scrap, improved uptime, and audit outcomes.

Training Implementation Best Practices

Effective training programs in metrology do more than transfer knowledge—they directly influence the consistency, accuracy, and defensibility of inspection results. But creating a program that delivers measurable value requires a thoughtful approach, structured delivery, and continuous evaluation.

This section presents best practices for implementing training in dimensional metrology, based on insights from quality leaders, audit findings, and industry training standards.

- Align Training with Operational and Quality Objectives

A successful metrology training program must be tightly aligned with the organisation’s operational KPIs and compliance requirements. This means:

- Mapping training content to real-world inspection processes (e.g. First Article Inspection, Gage R&R, in-process verification)

- Prioritising roles and skill gaps that impact compliance risk or throughput

- Linking individual learning outcomes to metrics such as:

- % of successful FAIR submissions

- CMM programming lead times

- Rework rates due to measurement error

Example: A MedTech facility reduced FAIR rejection rates by 26% within six months after aligning GD&T training with part-specific inspection scenarios during onboarding.

- Use a Competency-Based Framework

Rather than relying solely on course attendance, adopt a competency-based model where each technician or engineer is assessed on:

- Knowledge application (e.g. can they program a MODUS routine?)

- Interpretation accuracy (e.g. GD&T callouts)

- Process reliability (e.g. consistent Gage R&R results)

Tools to use:

- Skill matrices mapped to job roles

- Objective assessment checklists (e.g. from ASQ or NIST frameworks)

- Task simulations using historical inspection issues

This approach supports both audit readiness and internal promotions by clearly documenting who is qualified to perform which tasks.

- Tailor Delivery to the Audience and Context

Not all roles require the same depth of training. For example:

- CMM Programmers need hands-on sessions with test parts and software

- Quality Managers may benefit more from SPC interpretation and data-driven decision-making

- Production Technicians might need only operational-level training on fixture use and visual inspection

Best practice: Segment learners into categories (e.g. Operator, Technician, Engineer, Lead Auditor) and develop modular content relevant to each group.

- Combine Theory with Practical Application

Many training initiatives fail because they focus too much on theory without tying it to actual parts, processes, or measurement systems. Ensure that learners:

- Use the same metrology tools they’ll encounter on the job

- Work with actual production drawings and CAD files

- Validate training through live inspection scenarios

Example: In a Gage R&R training rollout, one company integrated the program with qualification runs of new fixtures. This resulted in faster validation and increased engagement from operators.

- Include Audit-Ready Documentation

Training logs should not just exist—they should be audit-ready. This includes:

- Records of attendance, completion, and competency evaluation

- Version control for training content

- Calibration of assessment tools to avoid subjectivity

- Re-training schedules for compliance with ISO 13485 and FDA expectations

Auditor insight: In 2021, the FDA issued over 200 Form 483 observations specifically related to training records that did not include evidence of effectiveness, not just attendance.

- Create Feedback Loops for Continuous Improvement

After training is delivered, follow up with:

- Performance data analysis (e.g. inspection error rates, programming lead times)

- Post-training interviews or surveys

- Peer reviews or mentor-led evaluations

Use this information to:

- Refine course content

- Update SOPs and work instructions

- Improve onboarding and upskilling strategies

Continuous improvement tip: Schedule quarterly metrology team reviews that include both a skill refresh and problem-solving session based on current quality challenges.

- Leverage Mentorship and Peer Learning

Given the informal nature of many metrology skills, mentorship remains an underutilised but powerful strategy. Pair junior staff with experienced technicians to:

- Reduce learning curves

- Preserve tacit knowledge (e.g. fixture setup nuances)

- Build internal training capacity

Formalise mentorship expectations with:

- Defined goals (e.g. achieve programming independence in 90 days)

- Regular progress tracking

- Feedback from both mentor and mentee

By combining structured training, clear metrics, and continuous feedback, organisations can develop a resilient and skilled metrology workforce that supports both quality outcomes and business performance.

Recommendations for Building a Resilient Metrology Workforce

In an environment where inspection accuracy, compliance, and production efficiency intersect, building a skilled and resilient metrology workforce is no longer optional—it’s strategic. The following recommendations are based on observed industry trends, expert feedback, and successful training implementations across high-precision manufacturing sectors.

These practices are aimed at quality managers, metrology leads, and operations executives responsible for talent development, risk mitigation, and performance improvement.

- Develop a Strategic Workforce Plan for Metrology

Workforce planning should extend beyond production or engineering and include metrology-specific roles. A strategic plan should:

- Forecast retirements or turnover among senior inspection personnel

- Identify emerging roles (e.g. Quality Data Analyst, CMM Programmer, SPC Specialist)

- Assess future equipment and software needs requiring new competencies

Tip: Use skill gap analysis and job task inventories to create a 3–5 year roadmap for capability development within the quality and inspection teams.

- Prioritise Cross-Training to Reduce Dependency Risks

Over-reliance on a single programmer or technician creates operational vulnerabilities. Implement cross-training initiatives so multiple team members can:

- Program and validate CMM routines

- Conduct Gage R&R studies

- Operate multiple inspection platforms

Implementation idea: Use job rotation cycles or assign “shadow tasks” during fixture qualifications to build secondary expertise across roles.

- Standardise Competency Models and Role Definitions

Create clearly defined roles with associated competency frameworks. For example:

- A Metrology Technician II might require proficiency in 2D drawing interpretation, SPC charting, and PC-DMIS basics.

- A CMM Programmer would require advanced knowledge of GD&T, offline programming, and measurement uncertainty.

These models enable:

- Transparent career progression

- Targeted training investments

- Objective performance assessments

- Integrate Training Metrics into Quality Dashboards

Tie training initiatives to measurable outcomes such as:

- % of FAIRs accepted on first submission

- Number of valid Gage R&R studies per quarter

- Average time to program new fixtures

This approach aligns learning with continuous improvement and enables upper management to see clear ROI.

Industry benchmark: Companies that track inspection-related KPIs tied to training (according to ASQ) show up to 35% fewer quality escapes year over year.

- Advocate for Formal Recognition of Metrology Skills

Many companies underestimate the value of formal metrology certifications. Advocate for:

- Third-party certification (e.g., NPL, ASQ, NIMS)

- Employer-sponsored credentials

- Inclusion of metrology as a recognised skillset in apprenticeship and degree programs

Why this matters: Recognised training frameworks increase credibility during audits and make talent pipelines more accessible.

- Build a Knowledge Retention Plan

To address the risk of knowledge loss from retiring staff:

- Capture fixture setup routines, programming tricks, and inspection logic as visual SOPs

- Record expert walkthroughs of part inspections or fixture calibrations

- Store inspection lessons in a searchable internal database

Long-term value: These assets reduce onboarding time for new hires and ensure process continuity across teams and shifts.

- Foster a Culture of Quality Learning

Create an environment where continuous learning in metrology is encouraged, recognised, and rewarded:

- Allocate budget annually for professional development

- Celebrate certification achievements or training milestones

- Provide time during work hours for skill development

Peer engagement tactic: Host quarterly “Quality Forums” where team members present inspection case studies, troubleshoot challenging measurements, or review regulatory updates.

By implementing these strategies, organisations can build a metrology workforce that not only meets current quality standards but is prepared to lead in areas of innovation, audit resilience, and digital transformation.

Conclusion

Metrology is no longer a static discipline confined to the lab—it’s a dynamic, data-driven function that underpins the reliability, safety, and compliance of manufactured products in sectors like MedTech, Aerospace, and Pharmaceuticals. As tolerances tighten, product designs become more complex, and regulatory scrutiny intensifies, the skills required of today’s metrology professionals have fundamentally changed.

This article has outlined the reality of that transformation, supported by evidence and industry benchmarks. From clearly documented skill gaps in GD&T and CMM programming to the impact of an ageing workforce and the increasing importance of digital measurement systems, the future of metrology training is being shaped by undeniable forces.

- The current landscape of metrology and the compliance risks tied to unqualified personnel

- Documented skill shortages across key inspection and data interpretation competencies

- External drivers like Industry 4.0 and ISO 13485:2016 that are influencing training demands

- The core competencies required of the future metrologist—from software fluency to statistical capability

- Evidence-based training models and delivery methods, including ROI comparisons

- Best practices for implementing effective training programs

- Actionable recommendations for building a resilient, audit-ready metrology team

The takeaway is clear: organisations that treat metrology training as a strategic function, not just an operational task, are better positioned to meet regulatory requirements, reduce inspection risk, and accelerate product validation timelines.

Building that capacity requires more than just sending staff to occasional courses. It calls for a measured, evidence-based training strategy rooted in defined roles, measurable outcomes, and continuous improvement. That’s why our team is not only highly skilled but also deeply experienced in providing tailored metrology solutions. We’re ready to support your specific measurement needs with precision and expertise. Get in touch with our experts today and discover how we can help elevate your metrology capabilities.

For Further Reading and Resources:

- ASQ: The Future of Quality in Manufacturing (2023)

- FDA 21 CFR 820 Training Requirements

- ISO 13485:2016 Clause 6.2 – Personnel Competence

- NPL Dimensional Metrology Framework

- SME Industry Reports on Workforce Readiness