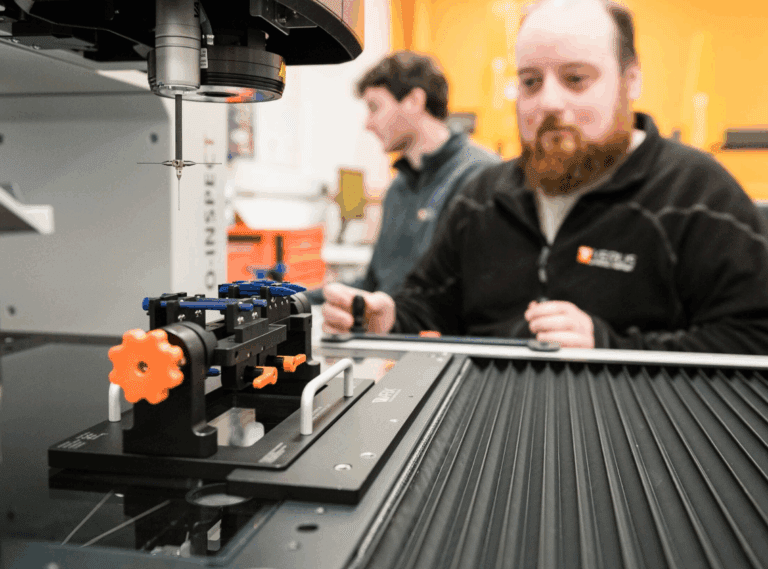

By Mark Devanney, Fixture & Industrial Designer

Here at Verus, we have the capabilities of producing a prototype or test fixture before a client commissions one for production. Additionally, we produce 3D-printed fixtures for certain uses and in this article, we’ll discuss the pros and cons of this.

What is a Prototype Fixture?

A prototype metrology fixture is generally a single station version of the production fixture. It is fully capable and finished to the same specification and quality. Generally, they are commissioned as proof of principle and built before the production fixtures. This will prove out the concept that we are putting forward.

A prototype fixture can be manufactured in such a way as to attach to the production fixture when complete. Therefore, it will be part of the multi-station production fixture unit.

What is a 3D Printed Prototype Fixture?

A 3D printed prototype fixture is as the name suggests, a 3D printed fixture using our in-house Eden 260V Polyjet printer. Our machine is capable of printing at a layer size of 16 microns and we use a material called Endur 450 which has similar properties to nylon. A 3D printed fixture can be used as a proof of principle and in most cases, this is all that it would be used for. However, we do use them as holding fixtures for metrology projects with longer runs or for tricky dimensions.

Advantages of a Prototype Fixture

A prototype single station fixture has all the benefits of a full production one.

The pros include;

- Quicker turnaround time

- Fully functional as per production build

- Proof of principle

- Great for functional testing

- A good way of ironing out any issues

- A problem-solving solution

- Full Gage R&R study can be carried out

- Same lifespan as a production fixture

Advantages of a 3D Printed Fixture

Most of the time when we make a prototype fixture, it is on the request of a client who needs a quick solution while waiting on the main jig that might not be commissioned for a few months. Therefore, we’ll take the concept we had in hand and create a single station version with the general idea in place.

The pros include;

- Very quick turnaround time

- Proof of concept

- Great for functional testing

- A good way of ironing out any issues

- A problem-solving solution

Disadvantages of a 3D Printed Fixture

The main issue with 3D printed prototype fixtures is shelf life. Therefore, as the material is a type of polymer they tend to wear quicker than their aluminium counterparts.

The cons include;

- Prone to more wear and tear

- Not a long term solution

- No Gage R&R studies carried out

Case Study

The best example of a prototype fixture would be the Cannula project commissioned by one of the world’s leading medical companies. The part was about the size of a tubular thumbnail and housed a fine needle. Secondly, it was quite delicate and as such the holding feature had to be as unobtrusive as possible.

The component only had a small area that could be used for holding it in place. Therefore, due to the measurements of the part, a prototype proof of principle fixture was created. In this case, the prototype would not be used again and so it was not anodized and brought to a full finish. However, it was done in every other way. From this prototype, issues were ironed out, changes were made and multiple iterations were created to get it right. We then created a single station fully finished prototype that would be able to become part of the overall fixture to fully analyze the design and build. The project required that the fixture be capable of scaling from 10 to 80 stations and the single station prototype would give us the insight needed to create the modular production fixture.

Furthermore, everything learned from the prototypes was brought into the production of the 10-station fixture and saved weeks of time in re-makes and modifications. Therefore, the project was completed ahead of schedule and we have since become the trusted fixture partner of the company.

Would you benefit from a Prototype Fixture?

We would say that no two projects are alike and that it depends on the components involved. However, in certain cases, a prototype fixture will be required as this allows us to prove out design concepts and communicate our ideas and fixtures function to clients. Additionally, it’s a more productive way for us to prove to a client that what we are building will work and to have a working fixture in hand for a possible First Off Inspection Report (FOIR) in a short amount of time.

Whether it be a 3D printed fixture to test the basic holding features or a full-featured single station fixture, a prototype fixture from Verus Precision is the best way to start off a project.