Industry Insight: 7 Metrology Trends in 2026

7 Metrology Trends 2026 For decades, metrology has been positioned as a downstream activity, focused on confirming conformance, supporting release decisions, and satisfying regulatory or customer requirements. While this role remains essential, it is no longer sufficient on its own. As part of the metrology trends 2026, manufacturers in regulated and high-precision industries are operating […]

Verus Metrology Partners Wins National Employer of the Year 2025 Award

We are proud to share that Verus Metrology Partners has been awarded a National Employer of the Year 2025 Award by the National Apprenticeship Office. The announcement was made last Thursday, 4th December, at a ceremony in the Gibson Hotel, Dublin, where eight outstanding employers from across Ireland were recognised for their leadership and commitment […]

ISO 17025 Accreditation: A Major Milestone for Verus

Achieving ISO 17025 accreditation is a defining moment for any organisation working in precision measurement, validation, and metrology. At Verus Metrology Partners, this achievement marks another step forward in our ongoing commitment to excellence, reliability, and customer-focused innovation. We are proud to announce that our company has officially been accredited to ISO 17025 by INAB […]

Environmental Impact: How Metrology Reduces Waste in Manufacturing

In today’s manufacturing landscape, sustainability is no longer optional—it is a strategic and regulatory imperative. Across sectors such as MedTech, Pharmaceuticals, Personal Care, and Aerospace, manufacturers face increasing pressure to reduce their environmental footprint, meet ESG (Environmental, Social and Governance) objectives, and comply with tightening regulations around waste, emissions, and energy use. One of the […]

Optimising Medical Device Manufacturing with Custom Fixtures

Medical device manufacturing requires extreme precision and reliability. From implants to diagnostic systems, every product must meet strict regulatory standards while performing flawlessly in clinical settings. In this environment, metrology is not just quality control—it underpins safety, compliance, and efficiency. However, accurate dimensional inspection is challenging when dealing with complex geometries, delicate materials, and micro-scale […]

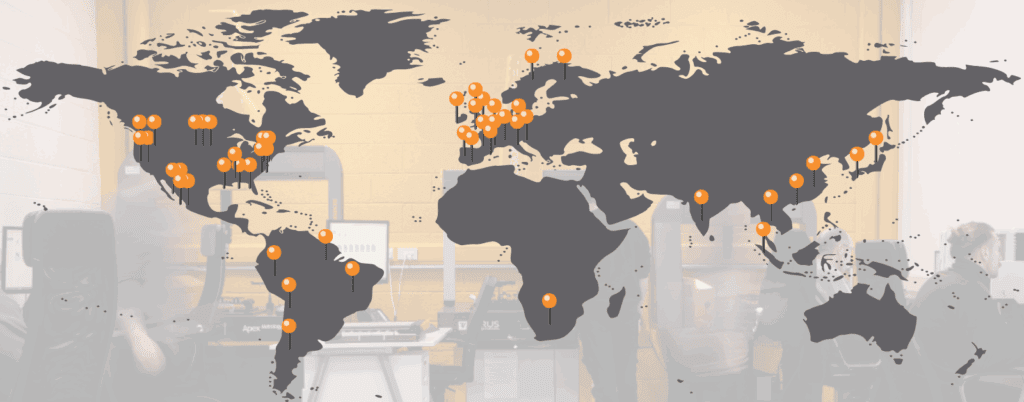

Inside the Business Development Team at Verus Metrology Partners

At Verus Metrology Partners, we are committed to transforming how the world approaches metrology inspection. While traditional technologies have remained largely unchanged for over 70 years, our focus is on delivering practical, modernized solutions that drive real results for clients worldwide. But at the heart of every innovation is a team devoted to ensuring that […]

Driving Innovation in Metrology: A Message from the Verus Leadership Team

At Verus Metrology Partners, our mission is clear: to revolutionize metrology inspection technologies that have remained unchanged for over 70 years. With a global client base and a relentless drive to deliver real solutions, we stand at the forefront of high-precision measurement innovation. Message from Our CEO At Verus Metrology Partners, we are committed to […]

Securing Compliance: Why Gage R&R Studies Are Essential

In regulated manufacturing environments-particularly within sectors such as Medical Devices, Pharmaceuticals, Aerospace, and Personal Care-the ability to make reliable, data-driven decisions is only as strong as the measurement systems behind them. Whether verifying a critical dimension on a catheter hub, confirming surface uniformity on a molded syringe barrel, or monitoring precision components in aerospace assemblies, […]

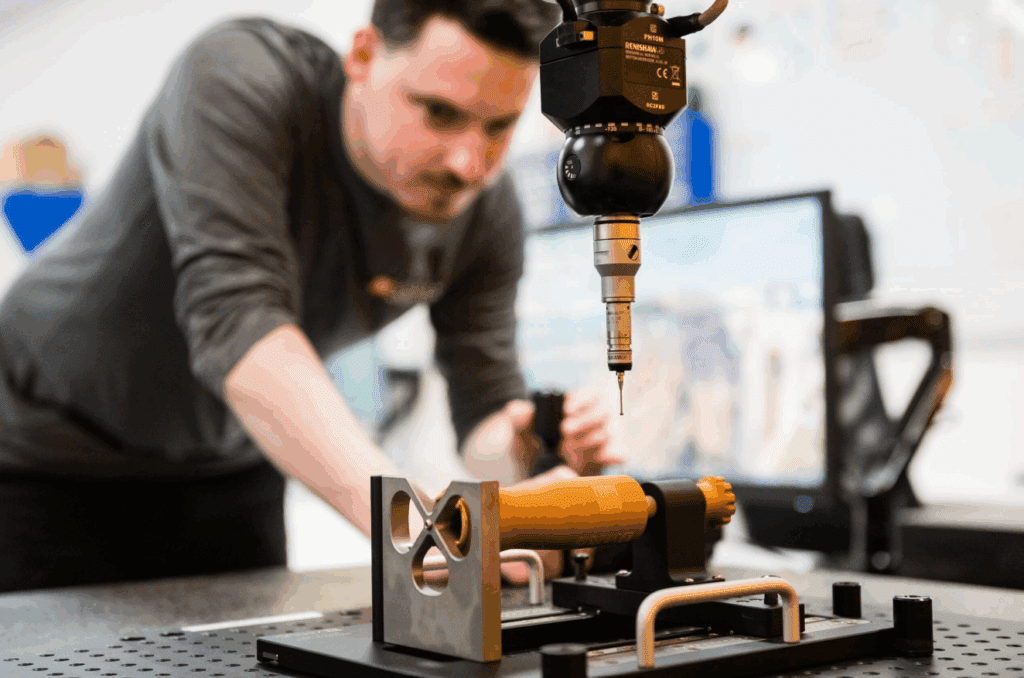

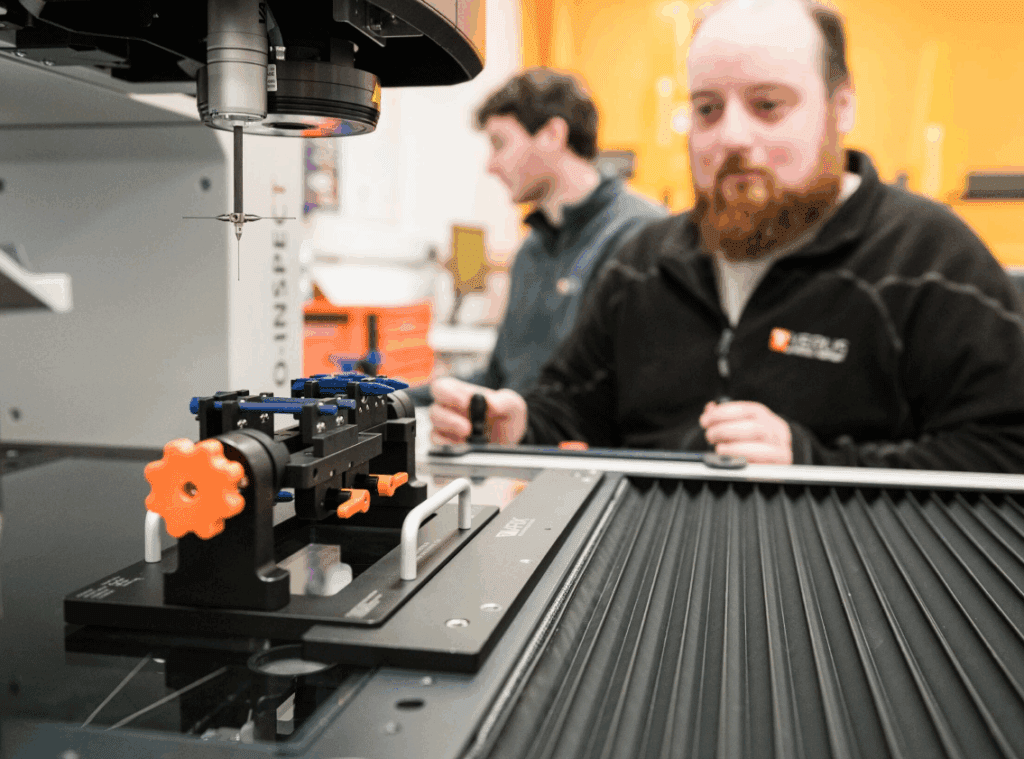

Welcoming the ZEISS CONTURA to Verus Metrology Partners

At Verus Metrology Partners, our commitment to delivering world-class metrology solutions has always been fueled by innovation, and accuracy. In line with this mission, we are proud to announce the latest addition to our metrology lab: the ZEISS CONTURA — a next-generation Coordinate Measuring Machine (CMM) that empowers our capabilities today and future-proofs our measurement […]

The Future of Metrology Training: A Data-Driven Look at Skill Development in Precision Manufacturing

In high-precision manufacturing sectors such as MedTech, Aerospace, and Pharmaceutical production, metrology is not a support function—it is a core driver of product quality, regulatory compliance, and patient safety. Whether verifying the geometry of an orthopaedic implant or validating the dimensions of a jet engine component, metrology ensures that each part meets its design intent […]