It’s STEPS Engineers Weeks! To celebrate, we investigate a career in Metrology Applications and what a day-to-day role in metrology looks like.

Metrology engineers are essential for companies across a wide range of industries. However, there is often a degree of mystery surrounding what metrology engineers do. This can be compounded by the fact that metrology engineers have varying duties. This last point is also one of the reasons why metrology is such a rewarding and satisfying career.

To help provide a better understanding of the role metrology engineers perform, we interviewed Verus team member, Jack Middleton. Jack is a Metrology Applications Engineer working in our office in Nottingham, UK.

1. What Is a Typical Day Like for You?

The day starts off with a meeting between the Ireland and UK metrology labs. This is where the engineers go over the projects that are ongoing, the challenges faced, and the work that is coming up. These meetings are essential for planning, and we keep them focused and straight to the point.

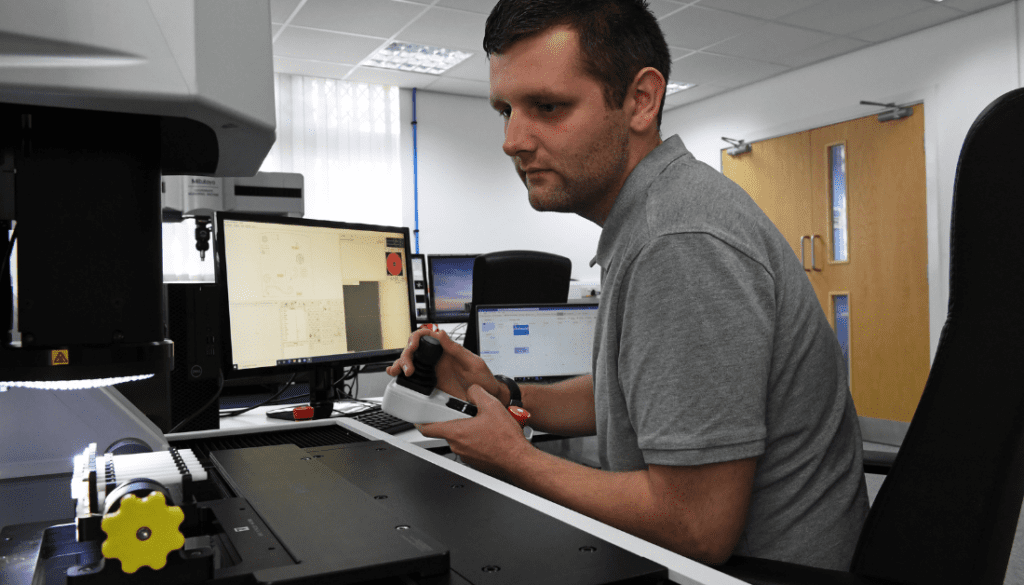

After that, anything can happen. We have assigned jobs, and they make up a substantial proportion of my day-to-day work. My jobs are mainly turnkey projects where a customer has a fixture, and I provide the program that will be used on the measurement machines. I also ensure the documentation for the program is accurate, and everything else associated with creating metrology applications.

We have a great setup here in Verus when working on turnkey projects. In the jobs I am working on, there is a machine set up in our facility in Ireland with a webcam aimed directly at it. I can control the machine and the webcam remotely, making it almost like being sat there in front of the machine.

As well as working on turnkey projects, I also provide support to customers experiencing issues. This could be any metrology-related issue from customers in any industry and anywhere in the world.

Recently, for example, I worked on machines for customers in Mexico, the USA, Germany, and Ireland – all on the same day. We use technologies like TeamViewer and Microsoft Teams to deliver this service. Without those technologies, it wouldn’t be possible for one metrology engineer to get around all those customers in a single day.

From my point of view, the plan in the future is to incorporate more travel to client locations to complete installs. I am looking forward to this traveling side of the job too.

2. What Machines Do You Use in Your Day-to-Work as a Metrology Engineer?

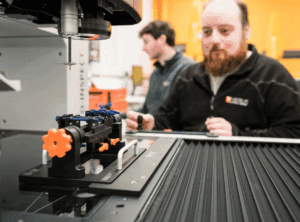

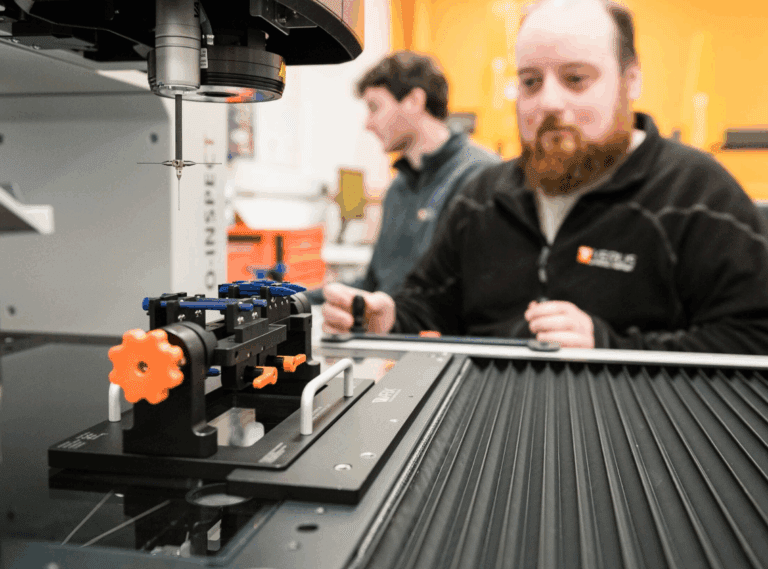

The machines and equipment we have at Verus are unlike anything I have seen before. I was working on CMMs for about five years before I joined Verus, and I would have given anything to have had the assets we have available here.

We have six OGP machines and four PC-DMIS CMMs, as well as a ZEISS Optical machine, a Micro-Vu Optical machine, and a Mitutoyo CMM.

This range of machines means we have access to anything that our customers will have at their facilities. This enables us to provide customers with the solution they require without the need for a conversion, as we can test the solution with a fixture we have here in-house. Once the solution passes repeatability tests in-house, we can ship the program and fixture to the customer, and it will just work.

That is a massive benefit for customers who need a turnkey package. It’s great for me also as a metrology engineer as it means I can deliver best-in-class solutions.

3. Does the Reality of Being a Metrology Engineer Match Your Expectations?

“That’s a tough one because when I started out, I had no idea what metrology was. My career started as an apprentice in the aerospace industry. From there, I worked my way up to engineer level.

Then by happenstance, a CMM job came up. I decided to try metrology and quality to see what it was like, so I went for it. I haven’t looked back since.”

4. What Parts of the Job of Being a Metrology Engineer Do You Enjoy the Most?

Dealing with issues that are challenging is a fantastic part of the job. When we get something from a customer, it is almost always to solve a problem. They need someone to find a way around the problem they are facing and to deliver a solution.

That’s what I like – looking at something and figuring out how we can make it work. It also makes every day different when you work as a metrology engineer. Every day brings a brand-new challenge.

It is also the beauty of turnkey metrology work. Every day is a different customer, different job, and different industry, which definitely keeps things fresh.

5. What Training Did You Go Through to Become a Metrology Engineer?

As I mentioned, my background was an apprentice in mechanical engineering. I have found this is true across the board, actually. Every metrology engineer I have encountered has a decent foundation in engineering.

As for specific training, I took courses on Hexagon PC-DMIS CMMs, as well as advanced GD&T training – geometric dimensioning and tolerancing training.

6. What Training Have You Done When Working at Verus?

Since joining Verus, I have had the opportunity to take part in a wide range of training programs to enhance my skills. This includes training on OGP and Micro-Vu software. The Micro-Vu training, in fact, was a week of training where a trainer from Micro-Vu came out to us at Verus to train all the metrology engineers. That was great as it meant we were able to immediately jump on turnkey projects to start supporting customers with Micro-Vu machines.

I also have training responsibilities at Verus, where I train our current apprentices on metrology application topics. Helping others develop their skills is another satisfying part of the job. It also demonstrates the commitment here at Verus to invest in skills and the future capabilities of the company.

7. What Advice Would You Give Someone Thinking About Metrology as a Career?

Metrology engineering really is a rewarding career. It’s about being able to make something work for a customer when they can’t see a way to make that happen. It’s about the whole process from fixture design, installation, and testing to providing comprehensive support.

You also get to build up really good relationships with customers – relationships where the customer knows they can turn to us when they are in trouble. That side of the job is really rewarding too.

So, my advice is that metrology engineering is a rewarding career path to follow, but the starting point is to get training at a base level of engineering. That training will give you the foundations for your future career.

Thinking about a career in metrology? Contact Jack Middleton, Metrology Applications Engineer on +44 (0) 115 967 7807 for more on how to kickstart your career. Moreover, be sure to subscribe to our NEWSLETTER to instantly receive blogs, customer updates and the latest company developments.