In today’s manufacturing world, where innovation and precision are crucial, custom metrology solutions are key to ensuring top quality and performance. These solutions go beyond ordinary tools; they’re specifically designed strategies to tackle the unique challenges of modern manufacturing, ensuring precision at every step.

The Need for Precision Measurement

As technology evolves, the demand for highly accurate and dependable measurement solutions has never been higher. Custom metrology solutions meet this need by offering specialized strategies tailored to the specific requirements of each product and process. They represent the highest standards of precision, supporting product validation and driving forward innovation.

Beyond Basic Measurements: Gaining a Competitive Edge

Custom metrology solutions are more than just measurements. They’re strategic assets that give businesses an edge in highly competitive markets. In sectors where there’s little room for error and mistakes can be costly, these solutions are the foundation for making smart decisions, staying in line with regulations, and constantly improving. They help manufacturers control their production processes, ensuring quality and efficiency are always top-notch.

Tailored to Industry Needs

The challenges one industry faces can be quite different from another. Whether it’s ensuring the intricate parts of medical devices are perfect, verifying the structural soundness of aerospace components, or checking the precision of automotive parts, custom metrology solutions are up to the task. They utilize the latest in measurement technology, such as 3D scanning and optical metrology, all customized for the task at hand.

Combining Technology and Expertise

The real strength of custom metrology solutions lies in the combination of the latest technology and deep metrology expertise. This powerful mix ensures that solutions are not only advanced but also perfectly aligned with the best practices in the industry. Developed in close partnership with clients, these solutions reflect both the current demands and the future goals of their manufacturing processes.

As we delve into the specifics of how custom metrology solutions benefit various industries, it’s clear they’re fundamental to modern manufacturing. These specialized solutions ensure quality, support innovation, and pave the way for a future where precision is guaranteed.

MedTech: Precision Metrology for Cutting-Edge Patient Care

In the MedTech industry, where engineering innovation, strict regulatory requirements, and the ultimate goal of patient safety converge, the need for custom metrology solutions becomes critically clear. The wide array of medical devices, from detailed surgical tools to complex implants and even wearable health monitors, presents unique measurement challenges. This section highlights how custom metrology fixtures are indispensable in navigating the intricate requirements of MedTech manufacturing, ensuring devices not only meet rigorous standards but also deliver on their promise to improve patient outcomes.

Addressing Complexities in MedTech Manufacturing

The vast diversity in forms, functions, and materials of medical devices brings unique challenges to the table. Custom metrology fixtures are crafted to handle these variations, allowing for precise and consistent measurements across different device geometries and materials. Whether it’s working with biocompatible materials for implants or flexible polymers for wearable tech, these specialized solutions provide the necessary flexibility to accurately assess a device’s dimensions, integrity, and performance under conditions that mimic real-life use.

Meeting High Regulatory Standards

The MedTech field is tightly controlled by some of the strictest regulations globally, like the FDA’s Quality System Regulation (QSR) and the EU’s Medical Device Regulation (MDR). These rules demand thorough quality control and traceability from design through to manufacturing and beyond. Custom metrology solutions are key for compliance, delivering precise, repeatable measurements essential for regulatory submissions and audits. By integrating custom fixtures and advanced tech, manufacturers can produce the detailed data required to ensure every device is up to the safety and performance standards expected worldwide.

Ensuring Unmatched Precision for Patient Safety

Given the high stakes in medical devices, where even minor inaccuracies can significantly affect patient safety and treatment success, the precision of metrology solutions must be second to none. Custom metrology fixtures are designed with this critical need in mind, enabling the measurement of essential features with extreme accuracy. This high level of precision is crucial not just when a device is first developed but throughout production, guaranteeing every unit manufactured matches the quality and standards of the originally approved design.

Fuelling Innovation in Patient Care

As MedTech companies strive to push the boundaries of what’s possible in patient care, custom metrology solutions provide vital support. By offering precise tools for measuring and validating new designs and materials, these solutions help speed up the development of groundbreaking devices. From advanced prosthetics that offer natural movement to minimally invasive tools that shorten recovery times, custom metrology plays a crucial role in moving new ideas from the drawing board to real-world application more efficiently.

In the MedTech industry, where the focus is as much on groundbreaking precision as it is on human lives, the role of custom metrology solutions is both critical and complex. By ensuring accurate measurement of medical devices amidst complex designs, diverse materials, and strict regulations, these solutions stand at the crossroads of innovation, compliance, and patient safety. Custom metrology fixtures are not just tools but fundamental elements in the mission to deliver technologies that enhance and save lives.

Aerospace: Precision Engineering for the Skies

In the aerospace sector, where the use of advanced materials, intricate designs, and the absolute necessity for safety and reliability come together, the demand for metrology solutions of the highest calibre is evident. Custom metrology solutions in this field extend beyond basic size and shape measurements. They incorporate sophisticated technologies and methods to tackle the complex challenges of inspecting aerospace components and assemblies.

Advanced Technology for Complex Materials

The aerospace industry utilizes a diverse array of materials, from traditional metals to innovative composites, each presenting unique measurement challenges. Custom metrology solutions for aerospace are equipped with advanced technologies like laser scanning and white light interferometry, supported by powerful software for detailed material analysis. This allows for accurate assessment of not just the external dimensions but also surface textures and internal structures, ensuring every part can withstand the extreme conditions of flight.

Precision in Design with GD&T

Accuracy in aerospace goes beyond simple measurements to include the precise specification of each part’s geometry and allowable variations, known as Geometric Dimensioning and Tolerancing (GD&T). Custom metrology fixtures are specially designed to support GD&T evaluations, allowing for the exact alignment and positioning of complex parts during inspection. These fixtures often need to be adaptable to handle the wide range of component sizes and shapes found in aerospace manufacturing, from tiny engine components to large sections of aircraft fuselage.

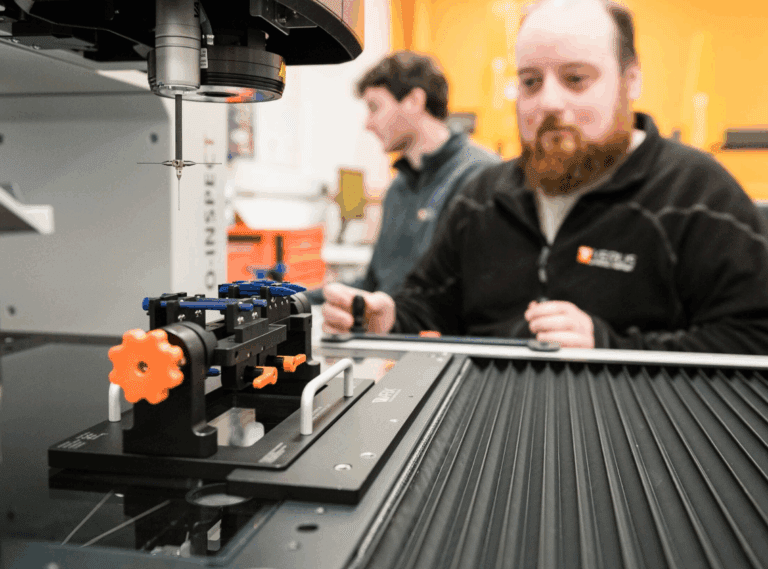

Custom Solutions for Assembled Accuracy

Aerospace projects typically involve assembling numerous components, each crucial to the aircraft’s overall performance and safety. Custom metrology solutions for these complex assemblies might include creating specific inspection plans that use coordinate measuring machines (CMMs), portable measuring arms, and laser trackers. This level of customization is key to ensuring not just the individual parts, but the entire assembly meets strict aerospace standards.

Ensuring Standards and Boosting Efficiency

Meeting aerospace standards and regulations is critical. Custom metrology solutions help by providing accurate, repeatable data needed for quality control and regulatory compliance. Moreover, optimizing inspection processes with these solutions can reduce inspection times and costs, contributing to more efficient manufacturing workflows.

Custom metrology solutions are indispensable in the aerospace industry, underpinning efforts to ensure quality, compliance, and competitiveness. By adopting these advanced, tailored solutions, companies can meet today’s high standards and prepare for tomorrow’s challenges in aerospace manufacturing.

Consumer Electronics: Navigating Precision in a Compact World

In the fast-moving consumer electronics industry, where devices get smaller and more complex by the day, there’s a razor-thin margin for error. This sector’s success hinges on the reliability and functionality of its products, directly affecting consumer trust and market position. Custom metrology solutions are crucial in this delicate balance, ensuring that as technology advances, precision remains at the heart of development and manufacturing.

Tackling Miniaturization Challenges

As gadgets become tinier, ensuring they’re built correctly becomes increasingly tricky. Every component must not only fit within tight spaces but also work flawlessly, often in varied environments. Custom metrology solutions rise to this challenge by offering precise measurement capabilities for the smallest scales. Techniques like atomic force microscopy (AFM) and electron microscopy, along with specialized fixtures and software, allow for detailed examination of tiny parts, confirming they meet strict quality standards.

Ensuring Devices Work as Expected

Beyond physical size, the complexity of consumer electronics includes intricate circuits and advanced materials. Custom metrology solutions address these aspects by analysing electrical paths, materials, and how different parts interact. This involves using specific equipment and software designed for electronic devices, providing insights into how well a product will perform its intended functions over time.

Supporting Fast-Paced Innovation

The consumer electronics sector is known for its rapid product turnover, with innovations hitting the market constantly. Custom metrology solutions support this brisk pace by enabling quicker and more efficient prototype validation and production checks. Precise and repeatable measurements help streamline the development process, reducing the time it takes to go from concept to consumer’s hands.

Enhancing User Experience Through Precision

Ultimately, the triumph of consumer electronics is measured by user satisfaction, which is significantly influenced by the product’s precision and reliability. Custom metrology solutions play a key but often unseen role in ensuring that touchscreens are responsive, cameras capture clear images, and wearable devices function consistently. By guaranteeing accurate assembly and component performance, these solutions contribute to the seamless operation that users expect, reinforcing brand loyalty and driving product success.

In the world of consumer electronics, where innovation and user experience reign supreme, custom metrology solutions provide the precision and reliability that manufacturers need to stay ahead. These tailored measurement strategies ensure that even as devices become more compact and complex, they continue to meet and exceed consumer expectations, securing a competitive edge in the bustling market.

Automotive: Driving Precision on the Manufacturing Floor

In the competitive world of automotive manufacturing, the quest for excellence is relentless. Custom metrology solutions play a pivotal role in this journey, providing the precision that’s critical to both vehicle performance and passenger safety. This sector demands not just general accuracy, but tailor-made precision that aligns with each manufacturer’s unique vision and the detailed requirements of each vehicle model.

The Essence of Precision in Automotive Components

Automobiles consist of thousands of parts, each essential to the vehicle’s overall functionality and safety. From the engine components to the smallest electronic sensor, every piece must match exact specifications for dimensions and material quality. Custom metrology solutions meet these needs by employing advanced measurement techniques like 3D scanning and laser metrology, capturing detailed data on every part’s shape, size, and surface condition. This ensures that each component can perform its role flawlessly, contributing to the vehicle’s reliability and safety.

Customized Solutions for Modern Manufacturing Challenges

As automotive makers embrace new materials and manufacturing technologies to enhance vehicle design and performance, the metrology challenges become more complex. Custom metrology strategies are crafted to tackle the unique issues presented by innovative manufacturing methods such as additive manufacturing or the use of composite materials. These personalized solutions ensure accuracy and quality control in production processes that might be beyond the reach of traditional measurement methods, linking manufacturing innovations directly to improvements in vehicle performance and safety.

Boosting Safety and Performance

Safety and performance are foundational concerns in the automotive industry. Custom metrology solutions are crucial for ensuring that vehicles are assembled precisely, with each component fitting perfectly and functioning as intended. This meticulous assembly is vital not just for the vehicle’s operational performance but also for its safety features to function correctly, directly impacting the well-being of passengers.

Paving the Way for Efficiency and Innovation

Beyond the immediate benefits of precision and quality, custom metrology solutions offer pathways to increased manufacturing efficiency and product innovation. By making the measurement process more streamlined and delivering actionable insights, these solutions help reduce production time and minimize waste. Moreover, the data derived from precise measurements informs continuous design improvements and innovation, allowing manufacturers to push the boundaries of automotive technology.

In the automotive industry, where achieving perfection is both a challenge and a requirement, custom metrology solutions are indispensable allies. They provide the unparalleled precision needed for modern vehicle manufacturing, support the integration of advanced materials and technologies, and contribute to the critical goals of safety and performance. These tailored solutions are not just tools but essential components in the quest to build safer, more efficient, and innovative vehicles for the future.

Future-Proofing Industries: Strategic Metrology for Tomorrow

As industries evolve with advancements in technology and shifts in consumer demands, the need for precision in manufacturing becomes even more crucial. Custom metrology solutions are not just about solving today’s measurement challenges; they’re about preparing for the future. These solutions bring the adaptability and scalability necessary to navigate upcoming technological trends and complexities in product design.

Preparing for Advanced Manufacturing

The future of manufacturing is heading towards more complex processes and materials, such as additive manufacturing and smart factories. Custom metrology solutions are designed with these future technologies in mind, providing the flexibility to accurately measure and assess a wide variety of materials and shapes. This ensures that as manufacturing processes evolve, quality and precision can keep up, making sure innovations in production lead to real benefits in product quality and efficiency.

Scaling With Product Evolution

As products become more sophisticated, incorporating new features and technologies, the demands on metrology grow. Custom solutions are built to scale, ready to handle more complex measurements with the same precision. This scalability ensures that as products push the boundaries of what’s currently possible, their quality and performance can be accurately assessed, maintaining high standards.

Adapting to Regulatory and Market Changes

The landscape of industry regulations and consumer expectations is always shifting. Custom metrology solutions offer the agility needed to quickly adjust to these changes, ensuring that products not only meet current standards but are also ready for future regulations. This flexibility helps companies stay ahead in a competitive market, building a reputation for quality and compliance.

Driving Continuous Improvement and Innovation

At its core, the goal of future-proofing industries is to foster an environment of continuous improvement and innovation. By providing detailed, accurate measurement data, custom metrology solutions fuel the insights necessary for product and process optimization. This cycle of measurement and improvement is essential for staying ahead of industry trends and technological advancements, ensuring industries are not just surviving but thriving in the future.

Future-proofing industries with custom metrology solutions is about more than maintaining standards; it’s about setting new ones. These tailored solutions ensure that businesses are prepared to meet the challenges and opportunities of the future, keeping them at the forefront of innovation and quality.

The Path Forward with Precision and Adaptability

Through our exploration of custom metrology solutions in sectors like MedTech, Aerospace, Consumer Electronics, and Automotive, a clear narrative emerges: precision measurement is the backbone of modern manufacturing. These tailored solutions go beyond the basic task of measuring, serving as strategic assets that propel industries forward by ensuring quality, fostering innovation, and maintaining compliance in a rapidly evolving landscape.

The Common Thread: Precision Drives Progress

Whether it’s ensuring the safety and effectiveness of medical devices, verifying the integrity of aerospace components, enhancing the functionality of consumer electronics, or securing the reliability of automotive parts, precision is the common thread that ties all these industries together. Custom metrology solutions, with their ability to meet specific industry challenges head-on, are indispensable in weaving this thread through the fabric of modern manufacturing.

Adapting to Change: A Strategy for Success

The future of manufacturing is undeniably complex, marked by advances in technology, shifting regulatory landscapes, and evolving consumer expectations. The adaptability and scalability of custom metrology solutions represent not just a strategy for coping with these changes but a formula for thriving amidst them. By preparing industries to meet tomorrow’s challenges with today’s innovations, these solutions ensure that businesses remain competitive, compliant, and at the cutting edge.

Continuous Improvement: The Cycle of Innovation

Custom metrology solutions empower industries to enter a cycle of continuous improvement and relentless innovation. By delivering precise and reliable data, they provide the insights needed for optimizing products and processes. This cycle of measurement, analysis, and enhancement is key to driving progress, allowing industries to not just keep pace with advancements but to actively contribute to them.

Precision and Adaptability as Pillars of Industry

In conclusion, the adoption of custom metrology solutions across various sectors illustrates a commitment to excellence and progress. These solutions embody the principles of precision and adaptability, essential for navigating the complexities of the 21st-century manufacturing landscape. As industries look towards the future, it’s clear that custom metrology solutions will play a pivotal role in guiding them towards a reality where quality, innovation, and efficiency are not just goals but guarantees.