In the world of manufacturing and medical technology, precision and accuracy are paramount. The ability to measure and inspect products and components with meticulous attention to detail is crucial to ensuring quality control and regulatory compliance. This is where metrology, the science of measurement, plays a vital role.

In this article, we will delve into the realm of metrology and explore how inspection and fixturing can significantly enhance quality control processes. We will also uncover the hidden value that metrology investments can unlock for businesses operating in diverse industries. Whether you are a metrology engineer seeking to improve your understanding or a project manager aiming to optimize quality assurance, this article is designed to provide valuable insights.

The Importance of Metrology in Quality Control:

Quality control is the backbone of any manufacturing or medical technology operation. It ensures that products meet specified standards, comply with regulations, and ultimately satisfy customer expectations. Metrology, as a discipline, involves the precise measurement of components, parts, and final products to determine their conformity to design specifications.

Metrology engineers and validation engineers play a critical role in this process. By utilizing advanced measurement techniques, such as coordinate measuring machines (CMMs), optical inspection systems, and 3D scanners, they can capture accurate data and identify any deviations from the desired tolerances. This data serves as a foundation for decision-making, process improvement, and ensuring the reliability and safety of the end products.

Unlocking Hidden Value with Fixturing:

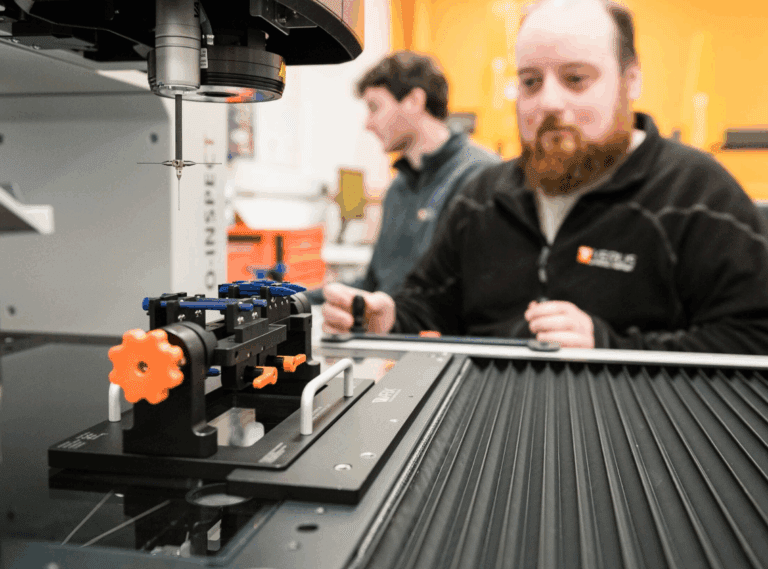

While inspection uncovers deviations from design specifications, fixturing plays a crucial role in mitigating these variations. Fixturing involves the design and implementation of specialized tooling or fixtures that securely hold components in place during measurement or inspection processes. By precisely positioning the workpiece, fixturing minimizes measurement errors caused by movement, vibration, or misalignment.

Medtech project managers and quality assurance managers can derive significant benefits from investing in robust fixturing solutions. Proper fixturing not only improves measurement accuracy but also reduces setup time, enhances repeatability, and boosts overall productivity. It enables faster inspection cycles, reduces rework, and ensures consistent quality throughout the manufacturing process.

The Hidden Value of Metrology Investments:

Investments in metrology infrastructure and technologies may seem like a significant financial commitment at first glance. However, these investments often yield substantial long-term benefits that far outweigh the initial costs. Here are some of the hidden values that metrology investments can unlock:

- Enhanced Product Quality: By implementing robust metrology processes, companies can achieve higher levels of precision and accuracy in their products. This not only improves customer satisfaction but also reduces the risk of recalls, warranty claims, and non-compliance issues.

- Process Optimization: Metrology data provides valuable insights into process performance and identifies areas for improvement. By analyzing measurement results, engineers can optimize manufacturing processes, reduce waste, and enhance overall operational efficiency.

- Regulatory Compliance: In industries such as medical technology, adherence to regulatory standards is of utmost importance. Metrology plays a crucial role in ensuring compliance with regulatory requirements, providing documented evidence of product quality and traceability.

- Cost Reduction: Effective quality control through metrology can significantly reduce costs associated with rework, scrap, and warranty claims. By identifying and addressing issues early in the production cycle, businesses can optimize their resources and minimize financial losses.

Conclusion:

Metrology, inspection, and fixturing are integral components of quality control in the manufacturing and medical technology sectors. By investing in metrology infrastructure, businesses can unlock hidden value and reap long-term benefits. Enhanced product quality, process optimization, regulatory compliance, and cost reduction are just some of the advantages that metrology investments can deliver.

To experience the power of metrology firsthand, we invite you to book a live demo with our team. Witness the impact of advanced inspection techniques and robust fixturing solutions on your quality control processes.

Book your live demo today and revolutionize your quality control processes.