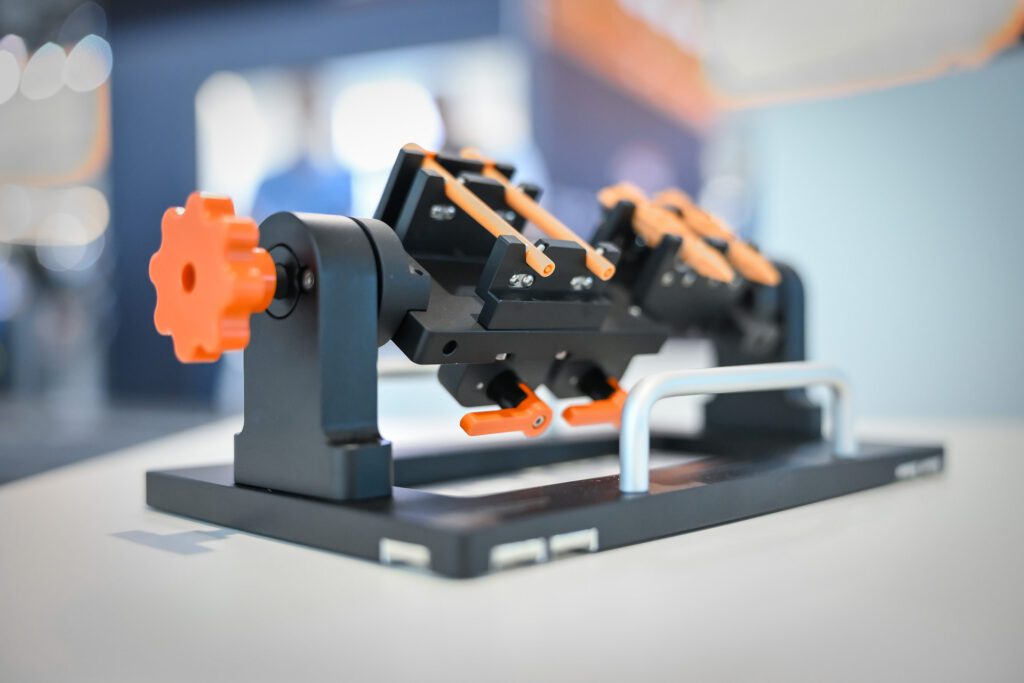

Metrology and CMM Fixtures

Ensure accurate, repeatable, and reproducible inspection processes with a fully tailored metrology fixture.

If you are looking for metrology or CMM fixtures, we can help. Your new fixture will securely hold and position your medical device products or components during dimensional measurement and other inspection processes. We can also provide fixtures for other applications, including to hold and position probes.

Here’s what you can expect from our metrology and CMM fixtures:

- Fixturing solutions designed to optimise your inspection process, driving efficiency gains and productivity improvements

- Delivering measurement accuracy by holding the part being measured securely and without any movement.

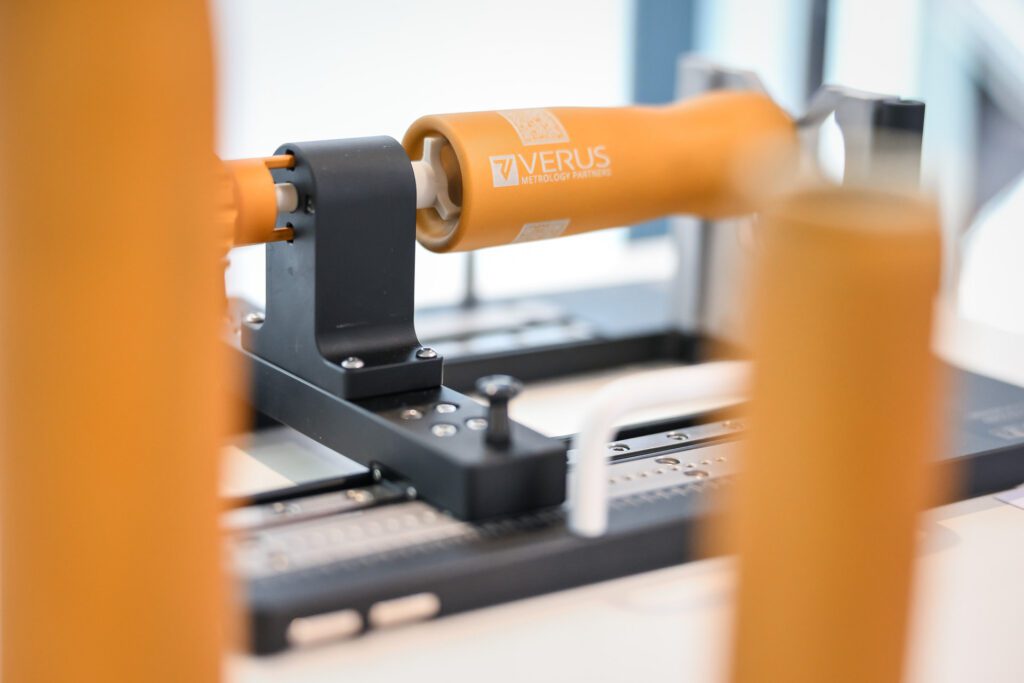

- Enhancing innovation in your inspection processes, such as through the introduction of rotational fixtures. With rotational fixtures, movement is defined and carefully controlled to enable measurements with minimal operator intervention.

- Enable quick, repeatable, and reproducible inspections.

- Increasing throughput in quality control processes, as well as inspection rates.

As well as supplying a lasting fixture, we’ll provide inspection routines using the software of your measurement system, while also providing you with access to expert support.

Turnkey Metrology and CMM Fixtures for All Types of Inspection Process

- CMM

- Vision system

- 3D scanner

- Articulating arm

- Optical comparator

- And more

Our Metrology and CMM Fixtures Development Process

You can benefit from our turnkey service to ensure you get a fixturing solution that delivers on your project requirements. Follow the fixture jpurney below.

1. Metrology and CMM Fixture Design

Our engineers will start the fixture design process by getting a complete understanding of your requirements, including the CMM in your facility, the products that will be inspected on the new fixture, and any other specific needs related to your quality and production processes. We’ll then make a recommendation on the best fixture solution, before following a seven-step design process.

2. Metrology and CMM Fixture Manufacture

Metrology and CMM fixtures are crucial to your compliance, quality, and production processes, so we don’t take any chances in the manufacturing phase of new fixture development.

Your new fixture, including the fixture plates and components, will be manufactured in-house at our advanced production facility, overseen by highly skilled CNC machinists, engineers, and toolmakers.

3. Metrology and CMM Fixture Qualification

4. Delivery, Installation, and Support

We’ll ship your newly manufactured quick and repeatable fixturing solution to your location, wherever you are in the world. We provide a full installation service, including remote installation using an innovative process developed and optimised by the Verus Metrology team. We provide CMM programming, too, and you will benefit from the ongoing fixture support that we provide.

Benefits of Our Metrology Fixtures & Solutions

- Medical device industry expertise

- In-house fixture manufacturing to ensure the highest quality standards

- Streamlined, simplified, and reliable inspection processes

- Ensures fast, accurate, and repeatable inspections

- Reduced operator intervention

- Reduced error rates and enhanced accuracy

- Enhanced consistency in measurement results

- Durable and long-lasting

- Increased throughput

- Enhanced quality department productivity

- Flexible solutions suitable for all platforms and inspection equipment

Metrology and CMM Fixture Family

Auto-Rotational Fixtures

Manual Rotator Fixtures

Multi-Station Fixtures

Large Cavity Fixtures

You can get a large cavity fixture fully customised to your requirements, both in terms of the products being inspected and your quality workflows. This includes multi-station solutions, component rotation options, and solutions suitable for the inspection equipment in your facility.

CMM and Vision System Solutions

Docking Systems

If you use multiple fixtures on the same metrology equipment for different products and inspection processes, our docking systems will help optimise and improve your inspection changeovers. The docking system we design for your facility will securely lock each fixture in place, ready for products to be inspected.