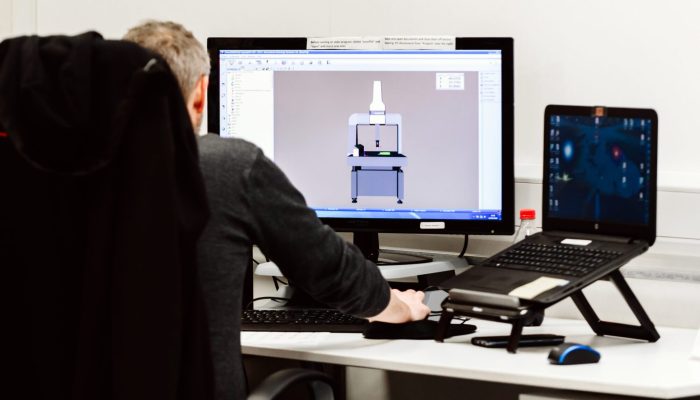

Our first-class service is comprised of a team of metrology experts, sophisticated software, and a strong focus on advancing the process of measurement through innovation that ensures our metrology solutions maximises efficiencies across our clients manufacturing procedures.

Maximise your capacity and Cap X ROI with our custom metrology inspection fixtures. Pair your inspection machine with a robust device that is designed, manufactured and tested to fit your project specifications. Our fixtures come complete with robust programmes that can be installed in your lab remotely or on site by one of our expert engineers. We have 16 in-house metrology systems and a diverse range of expertise across multiple engineers to ensure you have access to the best metrology partnership for your quality department.

Speed up your validation process, reduce risk, and improve the traceability of your inspection processes. We understand the importance of accuracy and quality assurance to your project and end clients. Our metrology solutions include fully traceable dimensional inspection, validation metrology, and gage verification. We can tailor our services to give you access to the experience and expert knowledge that will advance your metrology processes.

To be hidden

To be hidden

Get monthly metrology insights delivered straight to your inbox, and stay up-to-date with special offers.

Copyright © Verus Precision 2022

© OSD.ie Digital Agency Ireland 2022

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie records the user consent for the cookies in the "Advertisement" category. |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 1 year | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser IDs. |

| li_gc | 5 months 27 days | Linkedin set this cookie for storing visitor's consent regarding using cookies for non-essential purposes. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| VISITOR_INFO1_LIVE | 5 months 27 days | YouTube sets this cookie to measure bandwidth, determining whether the user gets the new or old player interface. |

| YSC | session | Youtube sets this cookie to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt-remote-device-id | never | YouTube sets this cookie to store the user's video preferences using embedded YouTube videos. |

| yt.innertube::nextId | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | YouTube sets this cookie to register a unique ID to store data on what videos from YouTube the user has seen. |

| Cookie | Duration | Description |

|---|---|---|

| _clck | 1 year | Microsoft Clarity sets this cookie to retain the browser's Clarity User ID and settings exclusive to that website. This guarantees that actions taken during subsequent visits to the same website will be linked to the same user ID. |

| _clsk | 1 day | Microsoft Clarity sets this cookie to store and consolidate a user's pageviews into a single session recording. |

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |

| _gat_UA-* | 1 minute | Google Analytics sets this cookie for user behaviour tracking.n |

| _gid | 1 day | Google Analytics sets this cookie to store information on how visitors use a website while also creating an analytics report of the website's performance. Some of the collected data includes the number of visitors, their source, and the pages they visit anonymously. |

| AnalyticsSyncHistory | 1 month | Linkedin set this cookie to store information about the time a sync took place with the lms_analytics cookie. |

| CLID | 1 year | Microsoft Clarity set this cookie to store information about how visitors interact with the website. The cookie helps to provide an analysis report. The data collection includes the number of visitors, where they visit the website, and the pages visited. |

| CONSENT | 2 years | YouTube sets this cookie via embedded YouTube videos and registers anonymous statistical data. |

| ln_or | 1 day | Linkedin sets this cookie to registers statistical data on users' behaviour on the website for internal analytics. |

| MR | 7 days | This cookie, set by Bing, is used to collect user information for analytics purposes. |

| pardot | past | The pardot cookie is set while the visitor is logged in as a Pardot user. The cookie indicates an active session and is not used for tracking. |

| SM | session | Microsoft Clarity cookie set this cookie for synchronizing the MUID across Microsoft domains. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | Facebook sets this cookie to display advertisements when either on Facebook or on a digital platform powered by Facebook advertising after visiting the website. |

| _uetsid | 1 day | Bing Ads sets this cookie to engage with a user that has previously visited the website. |

| _uetvid | 1 year 24 days | Bing Ads sets this cookie to engage with a user that has previously visited the website. |

| ANONCHK | 10 minutes | The ANONCHK cookie, set by Bing, is used to store a user's session ID and verify ads' clicks on the Bing search engine. The cookie helps in reporting and personalization as well. |

| bscookie | 1 year | LinkedIn sets this cookie to store performed actions on the website. |

| fr | 3 months | Facebook sets this cookie to show relevant advertisements by tracking user behaviour across the web, on sites with Facebook pixel or Facebook social plugin. |

| li_sugr | 3 months | LinkedIn sets this cookie to collect user behaviour data to optimise the website and make advertisements on the website more relevant. |

| MUID | 1 year 24 days | Bing sets this cookie to recognise unique web browsers visiting Microsoft sites. This cookie is used for advertising, site analytics, and other operations. |

| NID | 6 months | Google sets the cookie for advertising purposes; to limit the number of times the user sees an ad, to unwanted mute ads, and to measure the effectiveness of ads. |

| SRM_B | 1 year 24 days | Used by Microsoft Advertising as a unique ID for visitors. |

| test_cookie | 15 minutes | doubleclick.net sets this cookie to determine if the user's browser supports cookies. |

| UserMatchHistory | 1 month | LinkedIn sets this cookie for LinkedIn Ads ID syncing. |