We would like to thank all of our attendees for coming to the Verus Open Day last Tuesday 15th September 2015. I would also like to thank everybody for the excellent feedback and well wishes. The mix of new and existing customers was nice to see as it made it possible to give clients who may be considering partnering with Verus on their next new project a chance to hear directly from our existing customers and their experiences.

The general feeling from the many discussions was that people thoroughly enjoyed the presentations. They were both professionally presented and relevant. The mix of speakers, from industry and academia, was very well received.

Andrew Hodson, Managing Director – Verus welcomed everybody to our Open Day and outlined Verus’s history and achievements to date.

Our close neighbor Professor Richard Leach, University of Nottingham – Manufacturing Metrology Group, gave a thought-provoking presentation, which included his “Ambitions”. Professor Leach explained how he and his team will be carrying out basic research to develop the next generation of measurement tools for the precision and additive manufacturing industries. Professor Richard Leach also described how they intend building a world-class team of metrology experts, linking with key players including NPL, Huddersfield, Loughborough, and welcomed Verus Precision as part of this team.

Jon Banner, General Manager, Verus UK provided a detailed overview of the services that our UK office will be offering. Jon explained how important it is that the UK facility continues to work the ‘Verus way’ putting the customer at the forefront of all measurement decisions. He also explained that due to the high customer interest and subsequent workload in non-contact measurement that Verus UK has already invested in an additional OGP Flash 200 machine

Following the morning break, Louis Barnes, Senior Engineer – Wilde Analysis described the value of using Moldflow Analysis on a product at an early stage, therefore, highlighting and resolving potential issues that if left unaddressed could cause process and quality problems at a later stage. Louis focused on Shrinkage and Warpage, which ultimately ends up as deformation of the component. This is something that Metrology people are too often familiar with. This area of analysis was well received by the many Metrology persons present, as it gave them an insight into why components behave the way they do, thus ending up of out of specification when dimensional analysed.

Michael Nugent, Technical Director – Verus UK spoke of the importance of communication between Verus and their clients during Fixturing projects. Explaining how the learning process and knowledge gained over the last number of years in conjunction with our clients has enabled us to fine-tune a robust process. This process takes Verus from supplier to partner when dealing with fixturing projects. “ Communication and customer care, these are the 2 most important elements of fixturing projects “ as quoted by Michael Nugent

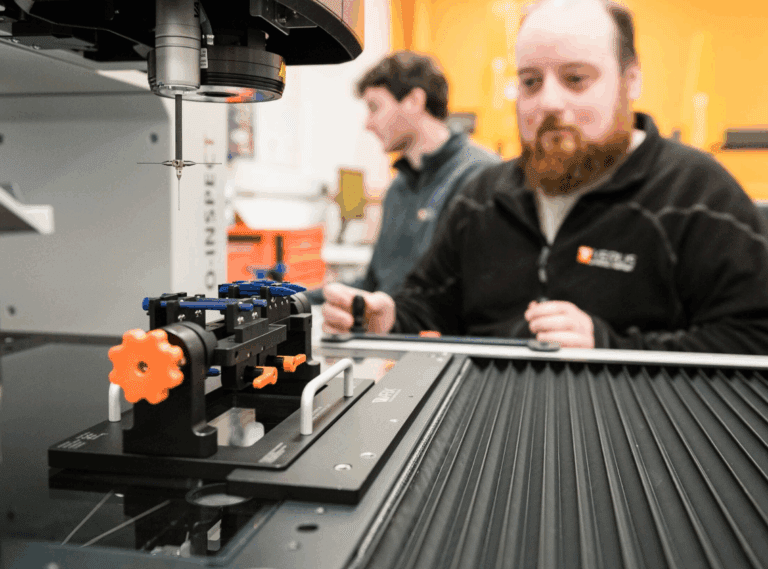

Throughout the day, there were break out periods when attendees had the opportunity to talk with like-minded people including the many Verus staff members that were on hand to answer questions. On view were Verus’s metrology equipment and a sample of fixtures that had been designed and manufactured at Verus. One of the highlights was the Auto Rotation Fixture that was running on the OGP 500, “which could be a game-changer” as described by one of our clients. This fixture is currently in development in Verus Ireland and we hope to be in a position to commercialise this new range of fixtures within the next 6 months.

We also had live demonstrations running of a Moldflow Analysis been carried out by Ronan Gallagher, Associate Autodesk Moldflow Simulation Analyst – Verus Precision, and a Fixture being designed by Damien Flaherty, Fixture Designer – Verus Precision. Well done lads on the day….

Peter Tune, Global Aerosol Development Technologist – Unilver HPC delivered a Case Study which described how Verus has worked closely with Unilever on designing and manufacturing fixtures for many of their new product ranges. Peter also emphasised how early involvement by Verus in these projects are vital to helping reduce time at the validation stages. Verus is considered a key part of the team when it comes to supporting Unilever.

We would also like to take this opportunity to thank all the team at Nottingham City council especially Rizvan Shafiq, Estates Office and James Mann, and Catherine Appleby, Invest in Nottingham. Without their help the process of locating and setting up in Nottingham would have been much harder.

We would also like to thank Ron Decelis, UK Trade, and Investment who in the very early stages compiled the lists of potential locations nationally and made the introductions to the local Teams.

Also, many thanks to all attendees, presenters, and Verus’s own Steph, Yvette, and Eilis who provided much-unseen support and assistance on the days leading up to the Open Day and on the Day itself.

Finally, keep an eye out for our next Verus UK Work Shop that will focus on the use of Moldflow Analysis, co-presented by Wilde Analysis and Verus Precision.