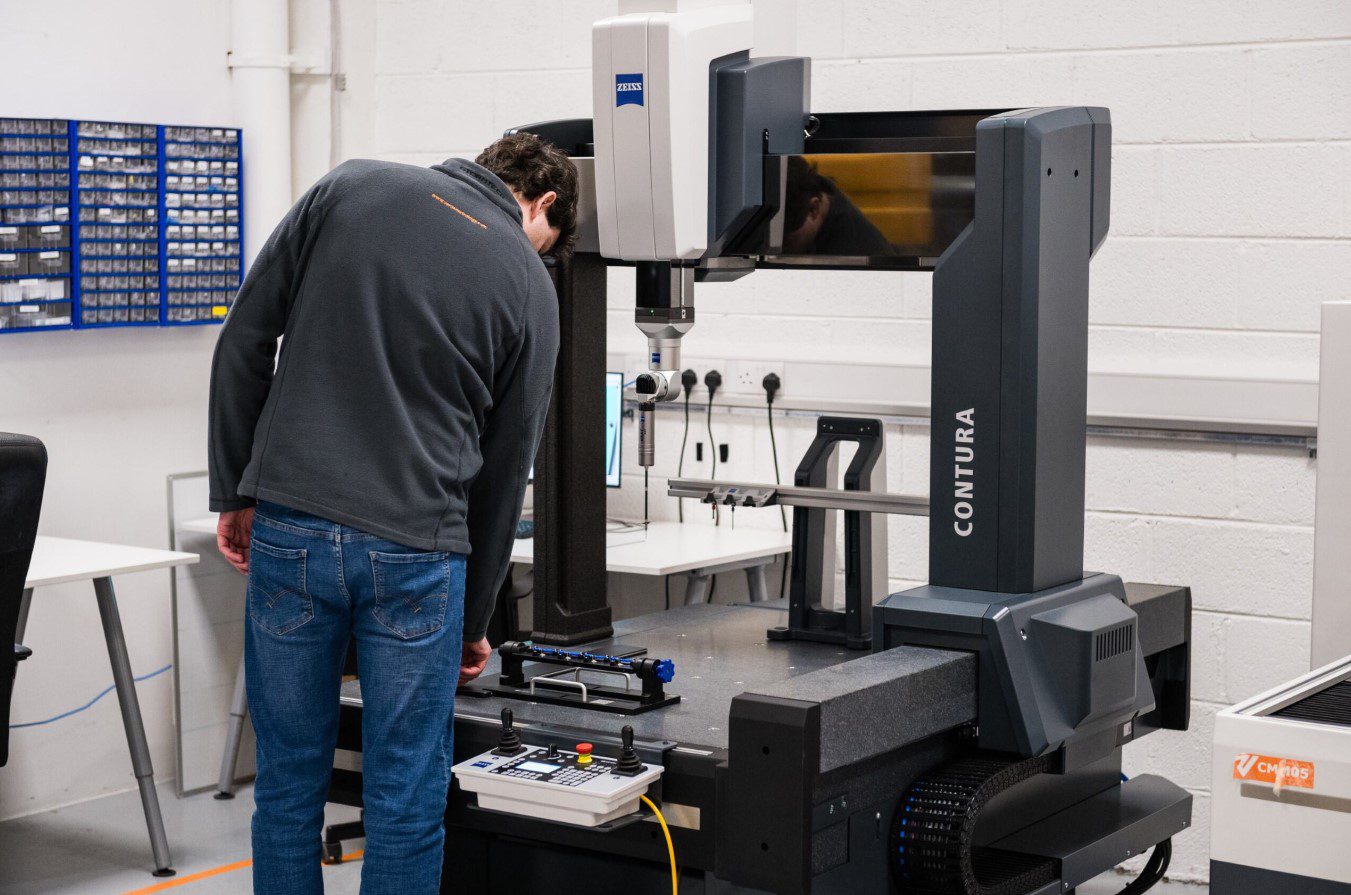

At Verus Metrology Partners, our commitment to delivering world-class metrology solutions has always been fueled by innovation, and accuracy. In line with this mission, we are proud to announce the latest addition to our metrology lab: the ZEISS CONTURA — a next-generation Coordinate Measuring Machine (CMM) that empowers our capabilities today and future-proofs our measurement needs for tomorrow.

Raising the Bar: Why ZEISS CONTURA?

The ZEISS CONTURA is more than a CMM; it is a dynamic platform designed to adapt with evolving industry standards, complex geometries, and stringent tolerance requirements. Equipped with mass technology, this new generation CONTURA allows seamless integration and interchangeability of sensor technologies. Whether tactile or optical, active or passive, articulated or fixed — CONTURA provides unmatched sensor flexibility in a single, cohesive system. The new CONTURA has a significantly larger measurement volume than the O-INSPECT (700 x 600 x 1000 mm vs. 500 x 400 x 300 mm), which allows us to accommodate larger fixtures on a single run.

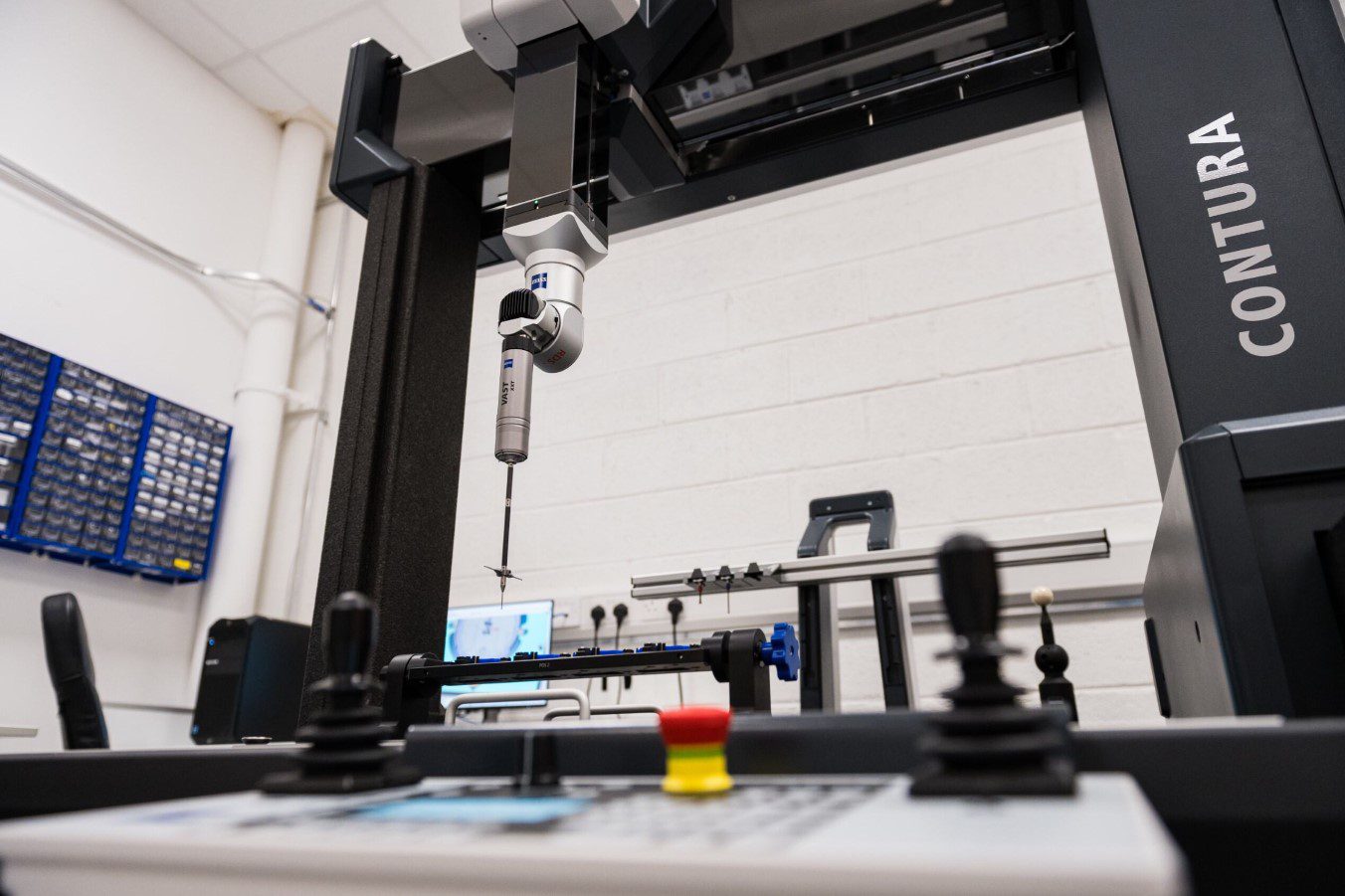

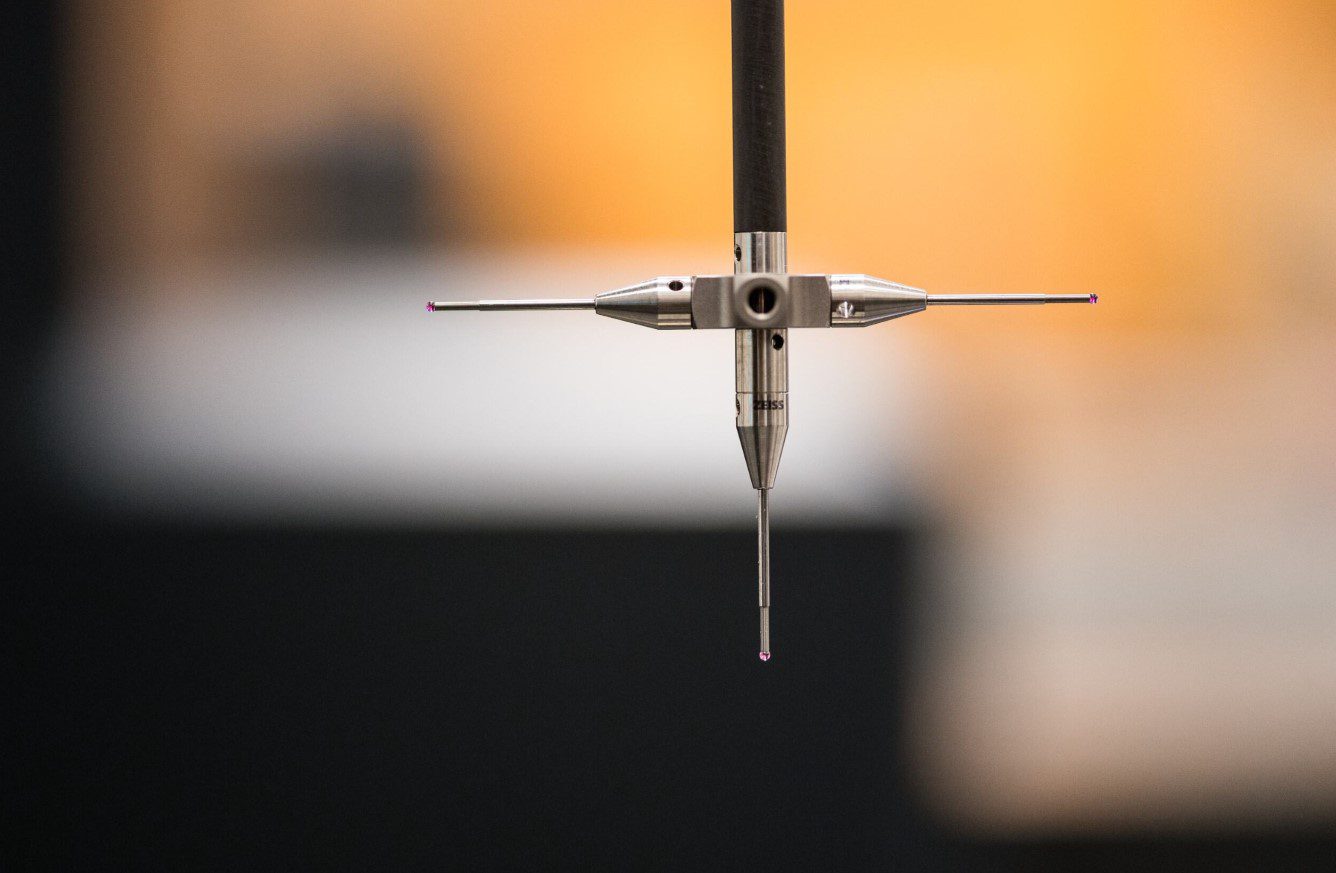

The CONTURA is equipped with a multi-angle RDS articulating head, which means we can use L-styli at various angles instead of relying on star probes as we did on the fixed-head O-INSPECT. This reduces the cost of stylus configurations and helps replicate our customers’ measurement setups more accurately. It is the most accurate CMM in Verus now and can achieve good GR&R results on dimensions with tight tolerances that the other CMM’s would struggle with. This ensures that our engineers can measure a diverse range of components with superior speed, precision, and ease — no compromise, no downtime.

Key Features Transforming Our Workflow

Modular Sensor Flexibility

Thanks to ZEISS’ unified interface and mass technology, switching between sensor types is now a matter of minutes, not hours. This multi-sensor platform supports everything from high-precision scanning probes to optical sensors, ensuring we can confidently tackle any part, material, or complexity with the right tool for the job.

4-Axis Measurement with Rotary Table

The flexible rotary table expands our ability to measure in four axes, enabling more efficient and thorough inspection of complex, multi-surface parts. This is a significant leap for our lab’s throughput and reliability, especially for intricate components that require rotational analysis.

Automated Probe Changing System

With the automated stylus changer, we can transition between probe configurations without manual intervention. This reduces operator workload and eliminates setup time, making our workflows more efficient and scalable.

HTG Option: Expanding Thermal Range

The High Temperature Gradient (HTG) option enables accurate measurements across wider ambient temperature ranges. This allows us to maintain measurement confidence even when working in less controlled environments — ensuring dimensional integrity where others may falter.

Performance Meets Ergonomics

Beyond its technical strengths, ZEISS CONTURA is built for the user. From its ergonomic design to its intuitive software interface, every element has been engineered to streamline usability and reduce fatigue. Our metrology engineers now enjoy a system that supports not just performance, but comfort and ease of use during extended inspection routines.

Building for Tomorrow, Starting Today

With CONTURA now installed and fully operational in our metrology lab, Verus Metrology Partners is equipped with the tools needed to meet the challenges of advanced manufacturing, tighter tolerances, and accelerated production timelines. Whether serving clients in medical devices, aerospace, automotive, or high-precision engineering, we are now even better positioned to deliver accurate, reliable, and fast measurement solutions.

Metrology Lab News

We’re excited to share that Verus Metrology Partners will be expanding our advanced inspection capabilities with the arrival of the ZEISS METROTOM 800 320 kV this August. Engineered for high-precision CT scanning of dense and complex materials, this cutting-edge system enables detailed metrology and inspection of components. At Verus, we’re committed to investing in state-of-the-art technology that drives precision, speed, and innovation. The METROTOM marks another major step forward in how we deliver trusted metrology solutions to our global clients.

📢 We’ve shared the full story on LinkedIn:

The ZEISS CONTURA isn’t just a machine – it’s an investment in the future of measurement. And at Verus Metrology Partners, the future is now. Looking to deepen your insight into our metrology lab, start a conversation with our experts or find out more about our metrology services? See what we’re all about.