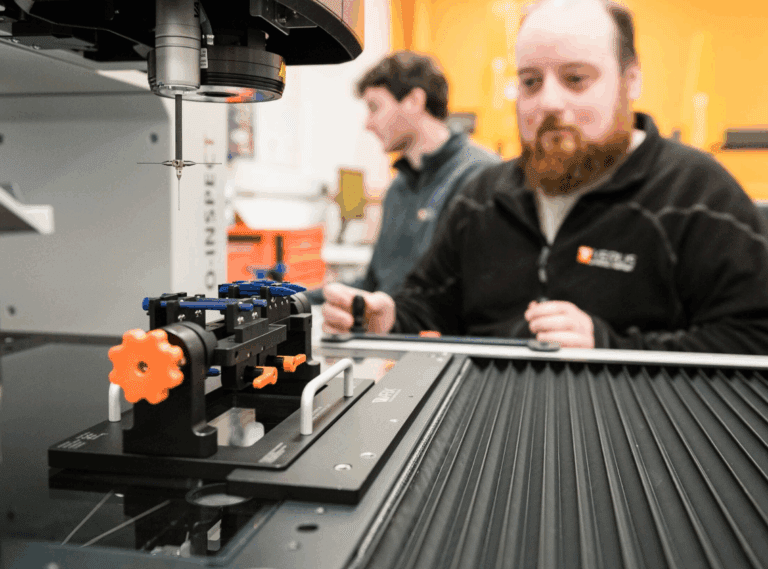

Project leader and Associate Director of Molding at BD Interventional business in Holdrege Jeffrey Reed and project coordinator, Andrew Allegretti, Sr. Staff Engineer of Injection Molding at BD Interventional business in Franklin Lakes worked collectively with the Verus team on the metrology process involved with two recent BD/Bard Projects for the Reynosa site in Mexico.

32-Station Crimp Collar Turnkey Metrology Fixture

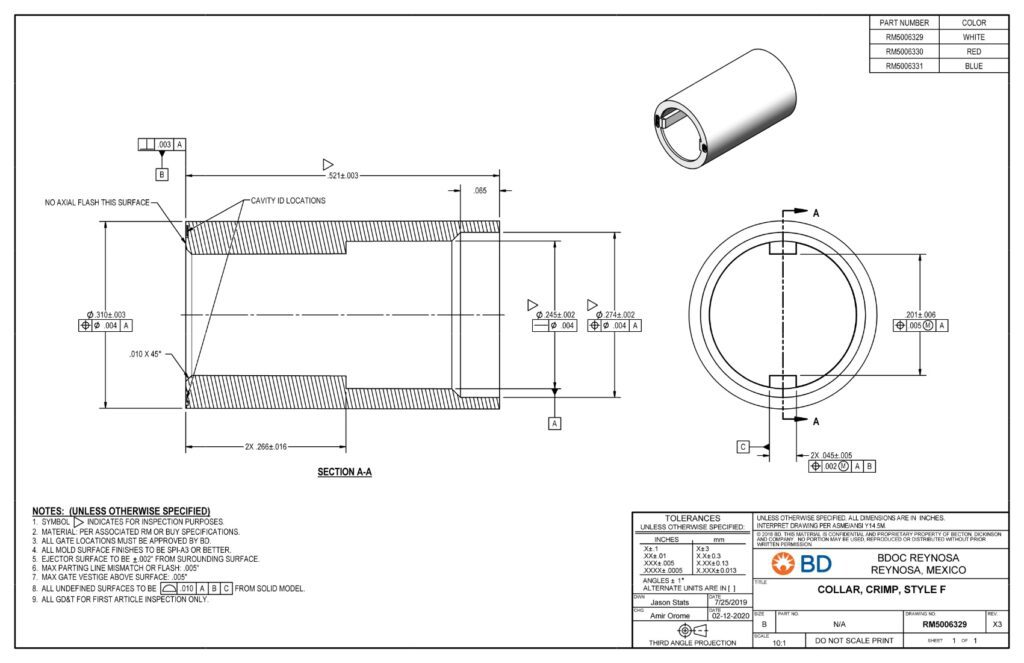

Crimp Collar Drawing Identifying Three Critical Dimensions

- Crimp Collar – BD/Bard Reynosa, Mexico

- Service: Turnkey Metrology Fixture Project

- Name: Crimp Collar

- Number of Parts: 32

- Dimensions: Three Critical Features Measured

The fixture needed to present the component for both probe and vision measurements without compromising the integrity of the parts. Therefore, it was important to consider the component’s geometry throughout the fixture design process.

The limited space on the smallest MicroVu machine proved challenging throughout the development of the 32-station fixture. However, through our inhouse expertise, clever design elements allowed for the successful development of the fixture.

To prove out the design concept, a single-station fixture was first created. This ensured it would work efficiently before moving on to the multi-up fixtures, which were two in total. The first 32-station fixture went to Prestek in California for measurements on an OGP Flash 302. The second fixture went to Reynosa in Mexico for measurements on a MicroVu Excel 502UC.

After programming the single-station fixture and retaining the POP, the process was later patterned out to the 32-station fixture. This helped to shorten the overall lead times and remain ahead of project timelines

The team then got to work performing a Gauge R&R, followed by fixture verification and programming. Shipment of the fixtures took place ahead of Michaels onsite installation visit to Reynosa.

Crimp Collar – 32 Station Manuel Rotation Fixture

Initially measured via vision, the crimp collar’s programme used a probe instead after issues began occurring due to flash on the components.

On-Site Installation at Reynosa

At a recent visit to the Reynosa plant, COO Michael Nugent met with Seth Guberman, Staff Engineer of Metrology at Franklin Lakes to complete the last phase of the Turnkey Metrology Fixture project. It was decided during this visit to deviate away from a go/no-go gauge to a more fit-for-purpose system.

Seth and Michael arrived on-site in February to run the Fixture Installation and Measurement System Analysis (MSA) on the single station, Proof Of Principle fixture. Armando Valenciano and Elizabeth Nicanor prepared the fixture and the sample components beforehand in advance of their arrival. Their support and availability throughout the day ensured the smooth running of the instalment.

Michael handed over the USB stick which held the MicroVu’s programmes and instructions and the Reynosa team swiftly installed and calibrated the new probes. Seth then used the pre-comprised instructions to get everything running with minimal adjustments needed. Although relatively effortless, the process was a learning opportunity for both Micael and Seth as neither had experience with the MicroVu software beforehand.

Some tweaks had to be made in anticipation of programme changes at Prestek to ensure programme equivalency was achieved. The process could then move on to replicating and collecting preliminary data.

The Reynosa team was then able to complete the GR&R and the POP fixture was fully MSA. This marked completion of installation and the fixtures were up and running in just two days.

Final Phase of The Project

Advancing to the next phase of this project, the G R&R on the multi-up fixture is scheduled for completion at both Prestek and Reynosa over the coming two weeks.

Having already passed GR&R internally at Verus, the team will be available to offer support and guidance if necessary to insure the successful completion of the project.

The ease of install and overall success of the project would not have been possible without the collaboration, communication and excellent preparation by both teams involved.

To find out more about our turnkey metrology solutions, contact our COO Michael Nugent on +353 (0)71 91 43506 (ext. 215).