Lean manufacturing involves eliminating or amending steps in a process that don’t add value. The aim is to improve efficiency, quality, and productivity using a systematic approach.

The concept of lean has its roots in the automotive industry, where it was first introduced as a concept in the 1980s by Toyota. Today, lean principles are used in almost all manufacturing sectors, including in the life sciences sector and, specifically, the medical device manufacturing industry.

In modern business environments, lean is not just applied to manufacturing, as the principles of lean can deliver benefits in a range of other business functions.

In this blog, we are going to explore lean manufacturing in high-volume, highly regulated industries such as medical device manufacturing. Specifically, we will look at how lean principles can be applied to metrology, quality assurance, and inspection processes.

Necessary, But Not Always Efficient

Quality control is an essential part of medical device manufacturing for a range of reasons. Top of the list is patient safety, but quality assurance processes are also important for brand reputation, regulatory compliance, OEE optimisation, and production line productivity.

The latter point is interesting. Rather than being viewed as a productivity booster, quality control processes are often regarded as getting in the way of the pure manufacturing element of a production line. This particularly applies when inspection processes take place away from the line.

In other words, it is not uncommon to view quality control processes as getting in the way of lean manufacturing.

Making Inefficient Inspection Processes Value-Adding with Advanced Metrology

It is possible to turn the perception outlined above on its head by using advanced metrology solutions that deliver on the principles of lean manufacturing, i.e., eliminating or improving wasteful and/or time-consuming steps in the inspection and quality control process.

This will not only make inspection and quality assurance processes more efficient, but it can also improve the overall performance of your production line. For example, by improving the speed and accuracy of the inspection process, deviations from normal tolerance ranges can be identified sooner so corrective action can be taken quickly, minimising the impact.

So, what are the advanced metrology solutions that will enhance lean manufacturing in your production facility? Here are the most important examples:

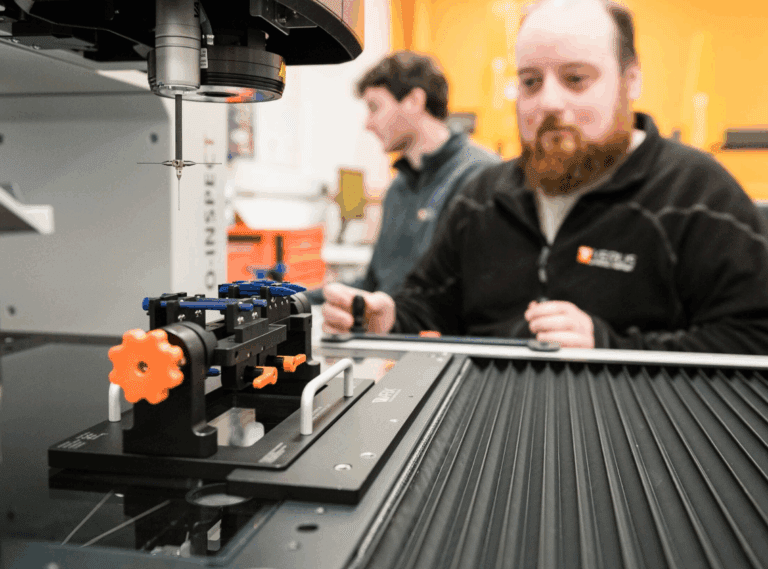

- Producing metrology fixtures and solutions that deliver the maximum number of measurements in the minimum number of steps

- Measuring multiple parts at the same time with multi-station fixturing

- Minimising human intervention in the inspection process as much as possible

- An example of the above point is to use auto-rotational fixtures that enable the inspection of all aspects of a part, including complex parts, without the need for a human operator to change the position of the part.

- Ensuring repeatability and reproducibility in metrology fixture design

- Using human factors engineering principles in the design of metrology fixtures to mitigate the risk of human error when operators must intervene in inspection and quality assurance processes

- Implementing inline metrology solutions to enable the inspection of parts directly on the production line. This approach to inspection eliminates multiple steps in the traditional, standalone metrology inspection process.

Modernising Quality Assurance in Your Facility with Lean Metrology Solutions

Metrology inspection and quality assurance processes are essential components of medical device manufacturing. With the use of advanced metrology solutions, the inspection process can enhance lean manufacturing in your facility. At Verus Metrology, we have experience developing and implementing solutions like those above, modernising the metrology and inspection processes in medical device manufacturing facilities around the world. To find out more and to speak to one of our metrology engineers, please get in touch.