In the 8 questions series hot seat this month is Verus’s Chief Operations Officer (COO), Michael Nugent. One-half of the founding members of Verus Metrology Partners, Michael coordinates all technical operations at Verus, overseeing activity in line with the design, manufacturing, and validation of our bespoke metrology fixture solutions.

We sat down with Michael to discuss his thoughts on the importance of good communication between metrology services providers and their clients, especially those working in the MedTech and Pharma Industries who are currently creating medical device solutions to the ongoing COVID-19 pandemic. He also tells us what he thinks separates the good from the great Engineers in today’s Metrology Industry.

8 Questions Series: The Industry

1. What does your day-to-day role at Verus Metrology Partners involve?

In a nutshell, as Chief Operations Officer, I hold the responsibility of overseeing the day-to-day operational function of the business. That is the short answer. The long answer, however, and if we were to talk more about the technical side of things, would mainly involve the creation and development of our bespoke metrology fixtures. This includes analysing initial concepts and deriving designs from those concepts while liaising with the client to ensure both sides are satisfied with the design before we proceed to manufacture. Consequently, on a normal day, you will find me in with the design or metrology teams, discussing measurement solutions for our clients or figuring out the next steps to enhancing our metrology fixtures.

Additionally, as COO, I am always looking to the future development of Verus Metrology. Securing its functionality to drive extensive and sustainable growth is a top priority for me. This means being open to new perspectives and finding better ways of doing things. Therefore, I am heavily involved in our research and development activity also. Essentially spearheading the business strategies to steer the company’s future in the right direction.

Everything we do at Verus Metrology must surpass client satisfaction. Therefore, it is my job to drive forward our operating capabilities, improving internal processes and technologies while implementing a collaborative approach to doing business.

2. Why did you choose this career? Most rewarding thing about your career?

I always had an interest in all things technical. Even in school, I fondly remember the metal work classes which I always looked forward to, the other classes not so much! So, I always knew I would end up doing something hands-on, creative yet technical and Toolmaking sounded very interesting to me.

Before Verus Metrology Partners, I was working as a Tool Maker or Mould Maker for various engineering companies in Co. Dublin before moving to Co. Sligo in 1993. It was during my employment in Sligo that I met Andrew Hodson, Co-Founder of Verus Metrology Partners, working together for several years as Toolmakers at Avenue Mould Solutions. We both had a passion for Metrology and held a sound understanding of the Plastics Industry. Hence, when we noticed a niche in the market for Sub-Contract Metrology, we knew we had to take a risk. Therefore, we left our current employment and started up something totally different and completely new to both of us.

Possessing expertise from long-standing careers in Toolmaking before branching off into our respective fields of Metrology and Moldflow Analysis, the collaboration led to the formation of the first independent Sub-Contract Metrology House in Ireland, Verus Metrology Partners (formerly Verus Precision). Today, we are the world leader for bespoke turnkey metrology solutions, serving global blue-chip organisations across the Medical Device, Pharmaceutical and Plastic Industries.

And the most rewarding thing…

To me, the most rewarding aspect of my career so far is seeing the company grow from just a hot desk at IT Sligo to where we are now. Being in a position where we can provide employment to the local community and overseas and create a good work environment that is also a happy work environment is one of the most important things to Verus Metrology. It must be mentioned that a huge portion of our success is down to the Verus employees. Surround yourself with the right people, people that force you to do better.

Additionally, witnessing a completed fixture being sent to a client and hearing the positive feedback is always rewarding. It validates all the hard work put into developing our metrology fixture solutions.

3. What personal characteristics do you feel are necessary to be successful in the Engineering industry?

In my opinion, I believe a successful Engineer is one who is a visionary. The difference between a good Engineer and a great Engineer is someone who is creative, innovative and a quick thinker. They envision future outcomes when making important decisions yet also know when to take risks and make assumptions.

It is very easy to over analyse a situation and take too long to decide. Therefore, a successful Engineer will be able to trust their instincts and make important decisions based on limited information, yet staying focused on the long-term goal. The Engineering Industry is an environment that changes quite rapidly. So, Engineers need to have a creative head on their shoulders and hold the capability of identifying opportunities in times of uncertainty. Due to the pace of innovation and the rapid advances in technology engineers should always be flexible and embrace change as and when it happens. Therefore, it is important to think ahead and be ready for the unexpected.

A good engineer has strong technical design ability too. Meaning they can perform the math and understand the primary and secondary physical aspects of what they are developing. This is so that when the time comes to build, it will work as expected.

4. What advice would you give to someone considering a career in Engineering?

Knowledge is power. If you are considering a career in Engineering, you should always be hungry for knowledge. There is ALWAYS something new to be learned whether you are one year or thirty years working in the industry.

The changes within this industry happen rapidly. Therefore, continuous professional development is necessary to keep up with the pace. This ensures you keep abreast of new developments in technology and highlights the value you bring to the table.

Michael pictured with our two UK Metrology Applications Apprentices, passing on his expert knowledge to the future of the Engineering Industry during a trip to Verus HQ.

I always believe you should try to learn as many aspects of Engineering as you can also. Expose yourself to various Engineering career paths. Be it Manufacturing, Design or Metrology, the sales side of things or the business side. Basically, try and expose yourself to as many aspects of Engineering/Metrology as you can at an early stage. It will prove valuable to you in the long run.

5. What trends do you think will shape the future of Engineering in Ireland and the UK? How do you feel Verus Metrology will respond to these trends?

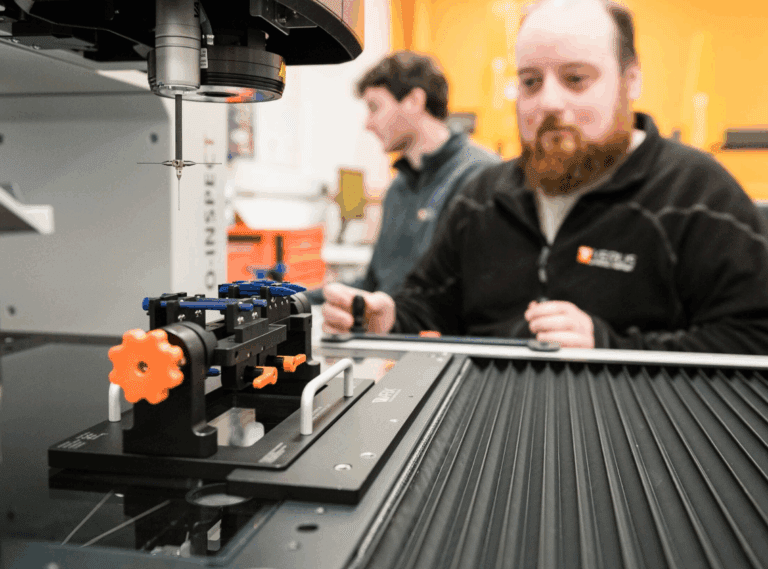

A significant development happening throughout many industries but perhaps more so prevalent in the Engineering, Manufacturing and Metrology Industries is Automation. Automation is a significant part of Engineering and Metrology now as it allows Engineers to be as fast, lean, and as efficient as possible when performing tasks. In terms of Metrology, Engineers are searching for ways to improve their in-house measurement activity. Be it producing a faster process, saving costs, or reducing their dependency on manpower, enable Engineers to focus on other value-add activities. Automation makes these requirements possible. Additionally, by introducing automation into the process of measurement, there is a better ability to ensure components are within tolerance limits and improved repeatability of inspection processes is achieved.

Owing to the increasing demand for optimised processes, automation certainly plays a huge role here at Verus Metrology. This is due to the increasing need for a swifter, more productive process of measurement. In terms of our fixtures, automation has allowed for the complete part inspection to be performed in one measuring set-up. Thus, reducing the need for human interaction, minimising the risk of human error.

We have already responded to this trend and we will continue to do so. We have invested heavily in automation as of late and through the introduction of our research and development department, we are consciously and continually looking into ways that we can improve our services to our clients or as we call them, partners.

8 Questions Series: A Bit About You

6. When you have a bit of free time, how do you spend it?

Any free time I have is spent with my lovely family or else out in the woods on my bike. I am an avid mountain biker and find nothing more enjoyable then flying down the rocky paths and reaching the end of the track somewhat safely.

7. What is your proudest accomplishment?

Of course, my proudest accomplishment is my kids Kate and Mark!

Aside from that, working together with Andrew in building Verus Metrology Partners up to where it is now is one of my proudest accomplishments. We started this together in 2008, knowing it was a good idea. However, twelve years on we could never have imagined we would be where we are today.

I hope the next twelve are as good as the last. Although with what we have in store for Verus Metrology, I have no doubt it will be even better!

8. What would be the title of your life autobiography?

I would have to say “Motion is Potion”. It was referenced to me by one of my physio buddy’s I cycle with. It sounds like it would be a good fit for my future autobiography!

To find out more about our bespoke metrology fixture solutions contact Michael Nugent, Chief Operations Officer on +353 (0)71 91 43506 (ext. 215) or Jon Banner, Group Applications and Development Director on +44 (0)115 7841934. To request a quote click here. Moreover, be sure to subscribe to our NEWSLETTER to receive our technical blogs, customer updates and latest developments.