At Verus, we have experienced significant growth in the demand for our metrology services since our beginning in 2008. So, what are the metrology benefits driving this growth?

By Nuala Baker

Metrology has always been a requirement in the manufacturing environment. In recent years, dependence on Metrology has increased dramatically and it has evolved into something that provides an invaluable insight into manufacturing processes and the parts that they produce. In addition, manufacturing tolerances have tightened substantially and continue to do so as high precision manufacturing becomes more demanding. All of these factors place more emphasis on the importance of high-quality measurement systems and high accuracy measurement analysis. This is made possible by the combination of advanced technology, time served experienced Metrology Engineers and cutting edge innovative Metrology Fixture solutions. At Verus we work with companies through all stages of the product lifecycle and have categorized the requirements and benefits of metrology as follows:

This is the beginning of any product. This is when the product is designed and the specifications are defined (including dimensional). It is the designer’s responsibility to ensure that what has been specified, in particular dimensional tolerances, is obtainable. Ideally, a Metrology expert would have input at this stage. Dimensional analysis may be required on prototype parts to confirm capabilities. If the manufacturing (including Metrology) capabilities are overestimated at this stage, it could spell failure for an entire project.

Process validation is the next stage for a product. During this stage, the manufacturing process is verified (including the equipment and whether it was properly installed and calibrated). Moving on from this stage involves declaring that the product has met its’ specification and is ready to be manufactured.

Depending on individual requirements the following Metrology may be required at this stage:

ISIR (Initial Sample Inspection Report)

This is a full dimensional inspection. It is a time-consuming activity to measure all dimensions which is why it is performed on a small number of parts (e.g. for a 2 cavity mold, 1 part per cavity would be measured). This is, generally, the only point at which all dimensions are measured (unless a major change is made to the manufacturing process/setup at a later stage). From this point onwards, a much smaller number of dimensions are used to track the manufacturing process.

Critical/Control Dimensions

A Critical Dimension is defined as a dimension that is critical to the function of a product. A Control Dimension is defined as a dimension that will indicate whether the manufacturing process is in control. This type of dimensional measurement is performed on a larger number of samples (e.g. 30 samples per cavity per-process setting) but on a much smaller number of dimensions (usually around 5 dimensions). This data is then statistically analyzed to find out whether the manufacturing process is in control and ultimately if it will remain within the specification limits over a period of time.

Critical/Control Dimension Measurement Systems

As well as measuring the Critical/Control Dimensions at validation, the measurement system that is used may be developed so that it can be used during manufacturing. This system can then be used to measure parts on a regular basis or simply whenever it may be required. A good quality Metrology fixture is recommended for such a measurement system. This fixture should be capable of holding parts ranging from the lower to upper specification limits (at a bare minimum) in a repeatable manner.

The final measurement system would be subject to MSA (Measurement System Analysis) in the form of a Gauge R&R (Gauge Repeatability and Reproducibility). A Gauge R&R will indicate whether a measurement system is suitable for measuring a certain dimension with regards to that dimension’s tolerance.

This is the final stage, which can only start after process validation has been successful. At this point, a part is being manufactured. This stage can last any length of time, from minutes to years. A regular dimensional inspection is desirable to ensure that any changes to the manufacturing process are detected.

The Critical/Control Dimension Measurement System mentioned previously, is an ideal method for keeping an eye on a manufacturing process. By performing regular dimensional inspection and statistically analyzing the data, it may be possible to predict an issue before it even occurs. This would prevent any losses e.g. dumping failing products, manufacturing line downtime, damage to a company’s reputation as a result of releasing bad products.

During this stage, further ISIRs may also be required if any change is made to the manufacturing process/setup e.g. cavity change to a mold tool, manufacturing process setting changes. Further measurements may also be required if any issues are experienced with the manufactured product.

Why choose Verus?

Here are some of the reasons why you should consider subcontracting your Metrology work to Verus Precision:

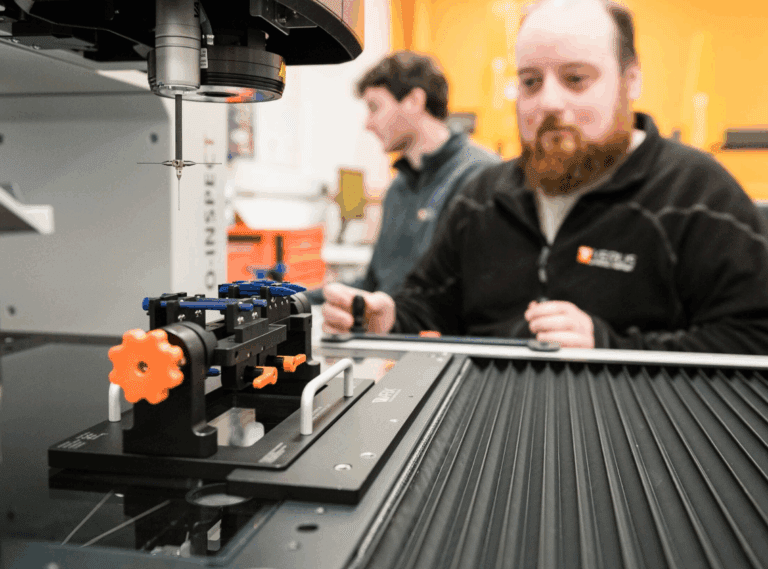

Equipment

We have access to a full range of equipment, from Coordinate Measuring Machines (CMMs) to Vision Systems. The manufacturers and software of this equipment are as varied as possible to allow us to be more flexible and to suit our customer’s needs. In terms of technology and equipment, our Metrology laboratory has everything you need to fulfill your everyday Metrology requirements.

For more information see verusmetrology.com/metrology/equipment/

Fixtures

The majority of measurement systems and measurement analysis require a fixture that is capable of holding parts of varying size in position in a repeatable manner. If a fixture does not hold a part correctly, it compromises the accuracy and reliability of all measurements involved. Usually, it is possible to hold a part using a combination of clamps, gauge blocks, vices, etc. However, if the measurement being performed is on a difficult part to hold (due to shape/size/material) or the same measurements will be performed on a regular basis. The manufacture of a custom-designed fixture may be necessary/justifiable. We have access to our own fixture design and manufacturing department that specializes in creating innovative fixture solutions on a daily basis.

For more information see verusmetrology.com/metrology-fixtures/

Expertise & Experience

In the area of Metrology, expertise and experience can be difficult to find. Our Metrology team has a depth of knowledge that extends beyond the operation and programming of CMMs and Vision Systems. It also includes years of experience measuring parts on a daily basis across a wide range of industries ( Medical, Automotive, Aerospace, Consumer Products). It can be guaranteed that however challenging a part may be to measure, our team will find the best solution.

For more information see verusmetrology.com/team/

In summary, the success of our Metrology department is completely dependent on our reputation within the industry. The majority of our customers are repeat customers and use our service on a regular basis. This is why you can rest assured that the Metrology we perform is of the highest standard of quality.