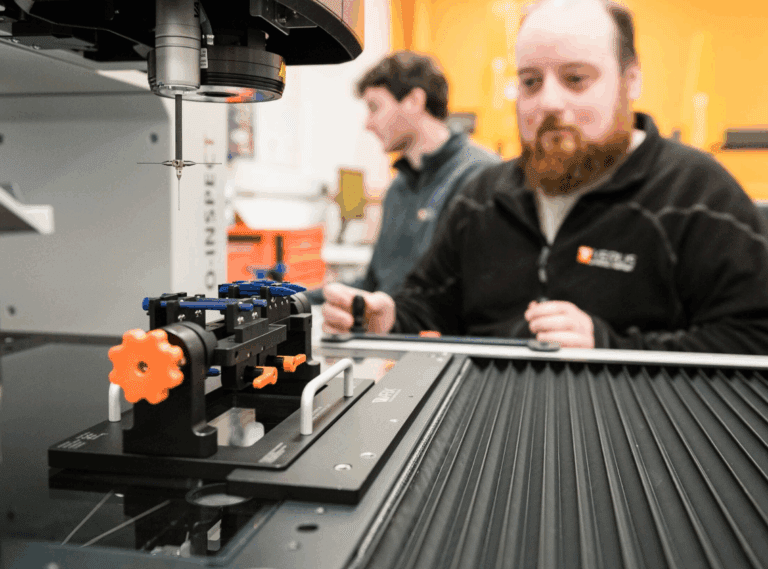

Verus Metrology Partners are delighted to announce a new partnership deal with Apex Metrology Ltd. The partnership will see Apex become an official supplier of Verus’ bespoke metrology fixture solutions.

Working together for over twelve years, the recent partnership cements the working relationship between Verus Metrology Partners and Apex Metrology. In addition to Verus’ bespoke inspection fixtures, Apex will wholesale Verus’ modular metrology fixturing kit – V-FIX™ – for non-bespoke fixture solutions.

Metrology Partnership is a Step in the Right Direction

The partnership has been described as a step in the right direction for the industry. Above all, both companies have long-established themselves as trusted measurement service providers to many of the world’s leading blue-chip organisations. Therefore, Andrew Hodson, CEO at Verus Metrology Partners, describes the partnering as a “natural fit” for both companies. He says:

We have a strong relationship already established with Apex Metrology that extends for several years now. The signed agreement formalises this and it means we are providing our clients with an additional level of measurement expertise. Therefore, by partnering with Apex, we can utilise their advanced capabilities in calibrating measurement inspection machines and CMM retro fittings.

Similarly, it’s the client-focused values held within the ethos of both organisations that are at the forefront of the partnership deal.

Andrew States:

Like Verus, Apex Metrology are a customer-orientated service provider. Striving to deliver the best customer experience to clients’, their core values include providing products & services of the highest quality, best value & to ensure customer satisfaction. Hence, by incorporating the same client-comes-first mindset to ours, it means both companies can work together to offer a superior turnkey metrology solution service.

Apex Metrology Ltd

Apex Metrology Ltd, who’s company heritage can be traced back to the days of Ferranti CMM’s, has been independently supporting multiple metrology systems and CMM users with Accredited Engineers for over 17 years.

The precision measurement solutions providers specialise in the supply of CMM Equipment, Installation, Maintenance, Hardware Support, Software Support and Training. Hence, their diverse manufacturer’s experience gives them the expert knowledge of CMM Applications, enabling the offering of comprehensive, more efficient measurement solutions.

Serving the Aerospace, Autosport, Automotive, Defence, Energy and Medical Device sectors, Apex Metrology offers best-value, high-quality economic solutions to several global blue-chip companies.

With an increasingly diverse customer base, Apex Metrology provides application solutions that address a wide range of specific client requirements. Apex is independently accredited for Applications & Service Support within the scope of ISO 9001:2015 and ISO 17025:201.

Brian Young, Managing Director at Apex Metrology, says:

Solutions that satisfy customer needs is a key deliverable from Apex Metrology. Forming a closer relationship with Verus Metrology Partners, we can provide bundled CMM solutions where the programming, validation and support offered are complemented by Verus’ experience in bespoke and standard fixturing.

Reviewing projects together at an early stage has proven successful as the specialist knowledge is available prior to commencing the work. Customer expectations of receiving a complete work-package means that with a reliable, experienced resource such as Verus Metrology available, it gives Apex confidence that customers will receive the best support/product for their application.

Verus’ Approved Partners Programme

Verus’ Approved Partners Programme brings together the best in the business. Industry leaders who share a passion for metrology, service excellence and who incorporate the same values into their company ethos.

The partnership sees Apex Metrology become the latest member to join Verus’ Approved Partners Programme.

Additionally, Verus has carefully selected programmers, trainers and equipment suppliers that have years of experience between them in the industry. As a result, clients’ can be confident in choosing the right solution for all their metrology needs.

To learn more about the Approved Partner Programme at Verus Metrology, contact Andrew Hodson, CEO at Verus Metrology Partners. Moreover, be sure to subscribe to our NEWSLETTER to receive our technical blogs, customer updates, and all the latest developments.