- Sleeve Part Chamfer – BD Medical, Drogheda

- Service: Dimensional Inspection

- Name: Measurement of Sleeve Part Chamfer

- Number of Parts: 20

- Dimensions: Chamfer Angle & Length

The Ace Every Quality Control Manager Should Keep Up Their Sleeve

Quality control managers in the MedTech industry are responsible for making sure that manufactured parts meet project specifications, tolerances, and regulatory requirements. While their role may vary from project to project, the pressure of meeting timelines remains. To do so, they rely on accurate Dimensional Measurement, reported in real-time.

However, obtaining the level of precision required can often prove difficult and time-consuming. The internal capacity may not be available; perhaps because someone is sick, a machine is down, an independent check is required or because they have an overflow of work they need to get through. Balancing those circumstances can limit the capabilities of quality control managers and threaten timelines.

But what if they had an ace up their sleeve allowing them to proceed when their CMM is overloaded? What if they could integrate an external department to their existing inspection team when required?

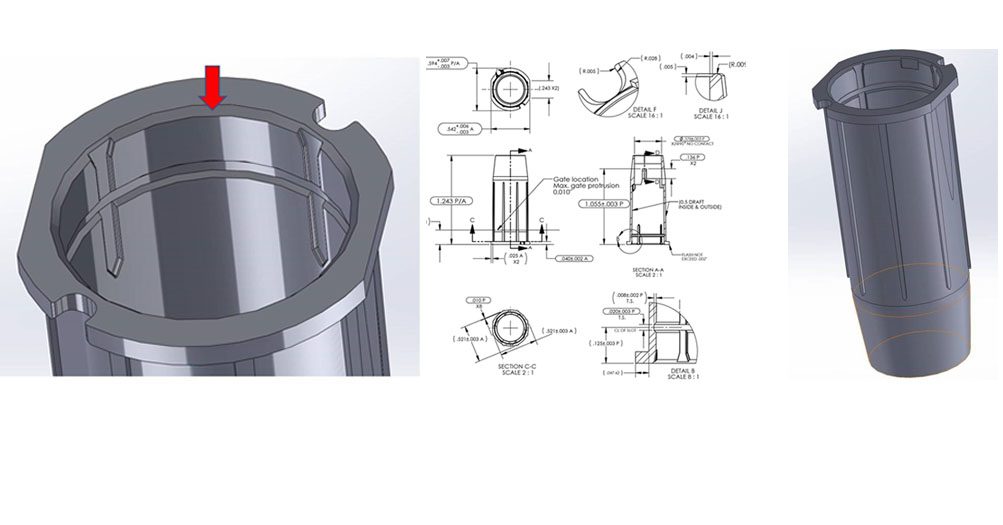

Measurement of Sleeve Part Chamfer – BD Medical, Drogheda

Paul Murray operates from BD Drogheda as Manufacturing Engineering Support. In order to complete the dimensional measurements of the Sleeve Part Chamfer, Paul contacted Michael Nugent from Verus Metrology Partners in November 2018.

Once initial contact was made, Paul established a direct line with Hazel Rooney, who managed this project from start to finish. He contacted Hazel once the measurement requirements had been finalized and a quote was sent the following day.

After studying the drawing it was decided our CMM machine would be best used for this job. A 0.5mm ball probe was selected to carry out the measurement. Hazel started a program by setting up the component to the drawings datum. The chamfer was so small it was best to localize all points taken to the one area rather than across the part.

- All features were created in a locked Y location (Y=0).

- Line 1 was taken on the top of the part in the X-axis.

- Line 2 was taken across the X-axis on the chamfer itself, for this the work plane was changed from XY to ZX.

- Again line 3 was taken in the Z-axis at 0 in the Y.

All lines were created out of a multiple of points (Min 10) that were equally spaced apart to get the most accurate result on this small area. These lines then allowed us to find the chamfer height and angle. This program ran across all 20 parts ensuring consistency in the measurements.

The dimensional inspection was completed in a half-day and the final report was sent to Paul.

Key qualities to consider when selecting a dimensional inspection service provider:

Finding a Dimensional Metrology lab that can not only provide turnkey solutions but also do so consistently can prove to be a daunting task if you are not equipped with the right measures.

Therefore, there are a few key factors to consider when trusting a Dimensional Measurement service to identify and correct component problems, resolve disputes, improve quality controls and possibly even shorten production cycles and improve overall operational costs.

Level of Expertise

Dimensional Measurement requires both training and experience. Choosing partners that have a wide range of expertise using a variety of materials across different industries can be very beneficial. When choosing sub-contract Dimensional Inspection, it is vital to ensure the team is trained in aspects such as OEM and GD&T.

Collaborative Process

Sourcing a provider that can operate as your external inspection department provides clarity, transparency and ensures measuring out of tolerance is a thing of the past. A direct line of communication and daily updates across all measurements are vital to the success of the partnership. You also need to know that contractor collaboration on their site is a possibility, should the need arise.

Equivalent Process

Each Dimensional Inspection project you agree with a sub-contractor should begin with equivalency testing, using identical or equivalent metrology machines and software to ensure the concurrent departments are moving in the same direction. The inspection team must understand that equivalency can also mean adopting methods and using the same reports as you. This results in a coherent metrology routine.

Non-destructive Inspection

Generating accurate dimensions without causing change or damage to your components is vital. Above all, collaborating with experienced metrology engineers that offer superior inspection methods is crucial, to ensure production and manufacturing costs are saved.

Lead Time Reduction

Accurate Dimensional Metrology, reported in real-time begins with a fast quotation process. Substituting sales, for a direct line with the engineer who will manage your project from start to finish, ensures no time is wasted. In addition, engaging with a Sub-Contractor who uses modular fixtures in-house can assure that inspection begins early and results in a fast turnaround of measurements.

Diverse Inventory

Partner with a Dimensional Metrology provider who has the capacity and provisions required to fulfill all your inspection service’s needs. The dimensional Labs must be fully equipped with a wide variety of inspection machines that are serviced and calibrated annually. Additionally, the laboratory conditions are equally as important. For instance, you must ensure that all CMMs and Vision Systems are placed in a monitored and temperature-controlled environment to confirm measurement sustainability. Trusting a lab that complies with the ISO:17025 accreditation can bring peace of mind.

Utilize a metrology team that uses advanced measuring instruments and technology to rapidly generate accurate verification of your designs and manufacturing processes and who can compile your data into comprehensive metrology reports.

This is the ace every Quality control manager should keep up their sleeve

At Verus Metrology Partners our focus is to add value to your product development and minimize your non-value-add activities. Therefore, the provision of our dimensional inspection service ensures shorter production cycles and improved quality controls through;

- Initial sample inspection- (ISIR Report)

- First Article Inspection – (FAIR Report)

- Component Measurement

- Tool validation metrology

- Multi-cavity mold inspection

- Reverse engineering

- Cavity verification/cad to part deviation

- Gauge R&R

- Inspection program creation

- Measurement procedure creation

- On-site metrology support

To find out more about the Sub-Contract Metrology services we provide contact Hazel Rooney, our Metrology Manager in Ireland on +353 (0)71 91 43506 (ext. 4). Moreover, be sure to subscribe to our NEWSLETTER to receive our technical blogs, customer updates, and all the latest developments.